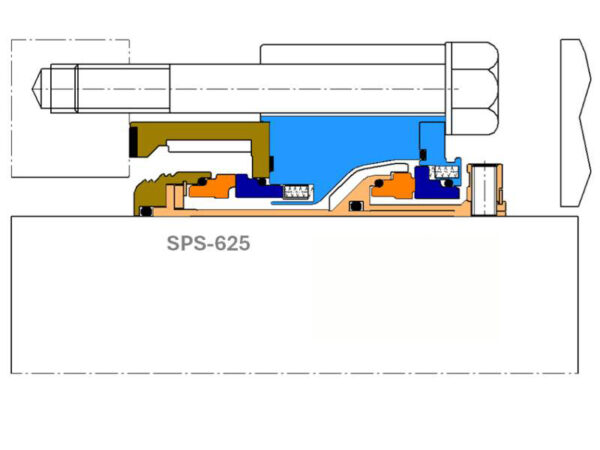

SPS-625 – External Mount Heavy-Duty Slurry Seal

SPS-625 – External Mount Heavy-Duty Slurry Seal

Overview

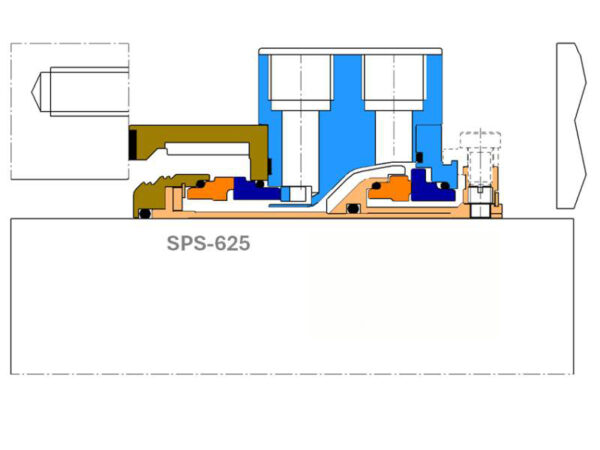

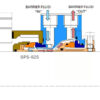

The SPS-625 by HydroMax Seal is a double cartridge mechanical seal equipped with an integral, bi-directional barrier fluid pumping ring and inboard wetted parts made from wear-resistant materials. This seal is purpose-built for heavy-duty slurry applications where the process fluid contains abrasive particles, making it ideal for the Mining & Mineral, Pulp & Paper, and Water & Wastewater industries.

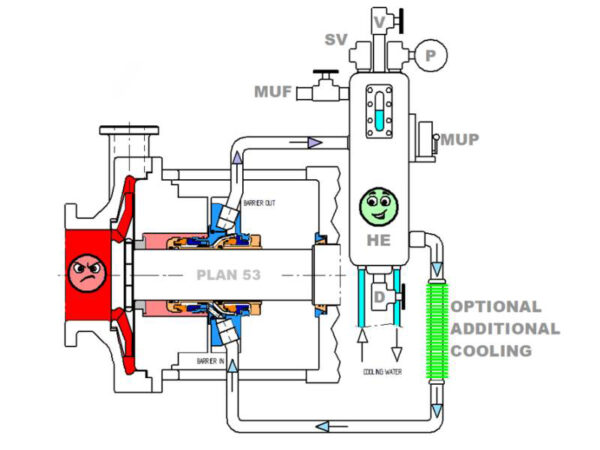

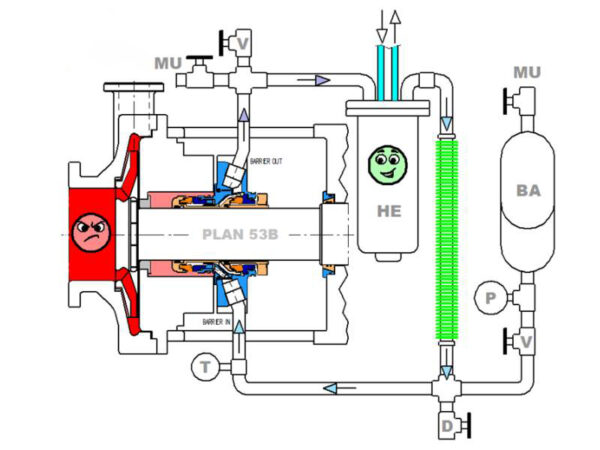

The innovative stationary seal design is delivered as a complete cartridge mechanical seal system and supports Plan 53, 53A, 53B, and 53C piping arrangements.

For equipment with small cross-section seal chambers, the SPS-625 can be mounted fully externally (where space permits). Its gland insert with built-in vortex breakers creates a large fluid volume over the inboard faces, optimizing seal performance and longevity.

Product Description

Design Features

- Wear-Resistant Components: Sleeve end cap and gland insert can be manufactured from a range of wear-resistant materials tailored for slurry duty.

- Fully Outboard Mounted: Ideal for equipment with limited seal chamber space, ensuring improved reliability in challenging slurry applications.

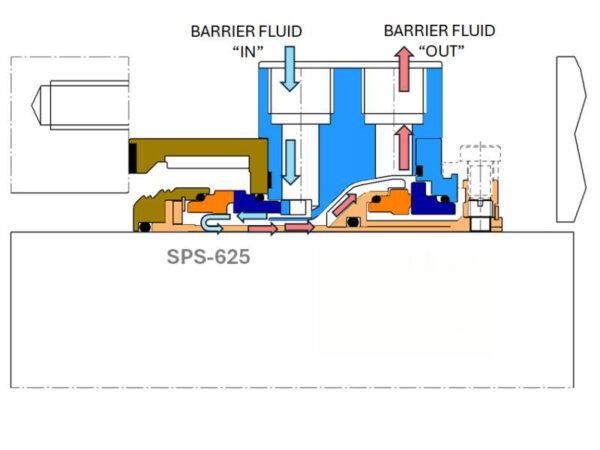

- Large Port Orifices: 1/2″ NPT Barrier Fluid In (BI) and Barrier Fluid Out (BO) connections support Plan 53 or 52 configurations.

- Directed Barrier Flow: Internal deflector in the gland guides fluid to inboard faces. Outboard outlet placement enables efficient heat removal on both seal faces.

- Vortex Breaker Design: Gland insert features integral vortex breakers to manage solids in slurry or particle-laden process media.

- API682-Compliant Clearances: Ensures proper radial spacing between rotating and stationary elements.

- Monolithic Seal Faces: Enhanced high-temperature performance.

- Self-Aligning Stationary Face: Ensures stability and performance at high shaft speeds.

- Multi-Spring Construction: Springs are isolated from the process fluid to prevent fouling and wear.

- Efficient Pumping Ring: Bi-directional pumping for reliable barrier fluid circulation.

- Plan 53 System Compatibility: Designed for seamless use with HydroMax Seal Plan 53, 53A, 53B, and 53C systems.

Technical Specifications

| Seal Shaft Sizes | All standard sizes supported |

| System Vessel Sizes | 3.17 gallons and 7.40 gallons |

| Inboard Seal Face Combinations | TC/TC Car / TC Ant. Car / RB SiC Ant. Car / TC RB SiC / RB SiC |

| Outboard Seal Face Combinations | Car / TC Car / RB SiC Ant. Car / RB SiC Ant. Car / TC TC / TC |

| Gasket Materials | Spiral Wound Stainless Steel, Graphite |

| Secondary Sealing Materials | Viton, Alfas, ERP, Kalrez |

| Maximum Shaft Speed | Up to 4,000 rpm |

| Pressure Rating | Up to 25 Barg |

| Instrumentation | Designed to work with Plan 53 piping systems |

| Temperature Rating | Up to 482°F |

Built for Extreme Slurry Conditions

The HydroMax SPS-625 is an advanced stationary seal engineered for demanding slurry environments with compact stuffing box designs. It integrates best-practice design standards and proven performance enhancements—detailed further in our technical blogs and white papers.

Typical Applications & Industry Use Cases

The SPS-625 is a double-cartridge mechanical seal engineered for heavy-duty slurry and abrasive media applications. Its design features — including a bidirectional barrier-fluid pumping ring, large barrier-fluid ports, a vortex-breaker gland insert, and an external-mount configuration — make it ideal for pumps handling high-solid slurries, abrasive slurries, or solids-laden process fluids where standard seals would wear prematurely.

Industries Served

Mining & mineral processing

tailings transfer, ore slurry pumps, thickener underflow/outflow systems.

Pulp & paper

pulp-stock handling, sludge/slurry pumps, paper-machine effluent transfer.

Water & wastewater treatment

grit/sludge pumping, wastewater slurries, solids-laden effluent streams.

General heavy process industries

any application requiring robust sealing under abrasive or particle-bearing fluid service where a double seal with barrier support is needed.

Equipment & Use-Case Scenarios

- Centrifugal or slurry pumps are used where the process fluid contains suspended solids, sand, grit, or abrasive particles.

- Pumps with thin or constrained seal chambers (“thin x-section stuffing boxes”) — in such cases, the SPS-625 can be mounted externally if space permits, avoiding the limitations of small-bore bore chambers.

- Systems requiring external barrier-fluid circulation (e.g., Plan 53, 53A/53B/53C support loops) for cooling, flushing, and face lubrication under abrasive conditions.

- Services with moderate to high shaft speeds and pressures (as the SPS-625 supports a broad range of shaft sizes, and the robust materials and design support demanding slurry conditions).

Why It Fits These Applications

- The integrated barrier-fluid pumping ring ensures continuous circulation of clean barrier fluid across the inboard and outboard seal faces, which helps wash away abrasive particles and maintain lubrication — critical in slurry service.

- Large ½″ NPT barrier fluid ports provide high flow capacity for barrier loops (Plan 53/52), ensuring effective cooling and flush even under heavy slurry loads.

- The gland insert with vortex-breaker geometry reduces turbulence and prevents swirling or vortex formation around the seal faces, minimizing particle impact and erosion near the sealing interface — improving seal life in abrasive media.

- The external-mount option allows use on pumps or systems where the stuffing box is too narrow for conventional double seals — offering a flexible solution without redesigning the pump housing.

- Self-aligning stationary face design and multi-spring construction (with springs located out-of-process fluid) improve reliability, reduce sensitivity to shaft misalignment or vibration, and enhance seal durability in harsh operating conditions.

Installation Guidelines

Before installation, thoroughly clean the pump shaft, seal-chamber bore (if any), gland face, and adjoining lines. Remove any scale, deposits, corrosion, or debris to ensure proper sealing alignment and prevent early wear.

If the pump has a narrow seal chamber, consider mounting the SPS-625 externally (space permitting) — this avoids constraints imposed by small stuffing box bores and simplifies installation. Ensure sufficient external clearance for the cartridge.

Carefully install the cartridge seal, aligning barrier-fluid inlet (BI) and outlet (BO) ports correctly for your barrier-fluid support system. Ensure the vortex-breaker gland insert is oriented properly to guide fluid flow.

Connect the barrier-fluid supply and return lines (Plan 53/53A/53B/53C or equivalent). Vent the barrier loop, confirm correct flow and fluid cleanliness, then ramp up to operational speed under monitored conditions.

Record baseline operational parameters — barrier-fluid pressure, flow, fluid temperature, seal-face temperature, and shaft speed — to support future condition monitoring and preventive maintenance planning.

Maintenance & Inspection Best Practices

- Monitor barrier-fluid loop performance continuously: track fluid flow rate, pressure drop across filters or strainers, fluid cleanliness, and fluid temperature. Any drop in flow or rise in temperature may indicate blockage, contamination, or barrier-fluid degradation.

- Periodically inspect the seal assembly (during shutdowns, if feasible): check seal faces for wear, scoring,g, or abrasion; inspect O-rings/gaskets and springs for integrity; and examine barrier-fluid ports and passages for deposits or clogging.

- Maintain a log of operational conditions: fluid composition (solids content, abrasiveness), shaft speed, pressure, temperature, number of start-stop cycles, vibration, and any abnormal events. Use this data to forecast maintenance intervals and identify trends.

- Replace secondary seals (O-rings, gaskets) and refresh barrier-fluid and filtration components on a planned schedule, rather than waiting for failure. Keeping barrier-fluid clean and well-filtered significantly improves seal life in slurry service.

- If slurry conditions worsen — higher solids load, more abrasive particles, more corrosive fluid — reassess seal materials and barrier-fluid plan; consider upgrading to more wear-resistant face materials or more robust support systems.

Service & Support Options

- Pre-installation consultation to ensure correct specification: selection of appropriate wear-resistant materials (for wetted parts, faces, and gland insert) based on slurry chemistry, abrasiveness, and operating temperature.

- Field or remote commissioning assistance to verify barrier-fluid loop setup, orientation of ports/insert, barrier-fluid flow and cleanliness, and to monitor seal-face temperature under live load conditions.

- Spare-parts kits tailored to SPS-625: including seal faces, gland inserts, O-rings/gaskets, springs (if applicable), barrier-fluid pumping ring components, and port hardware — to support fast maintenance and minimize downtime.

- Upgrade or retrofit support: if process demands increase (e.g., heavier slurry, more abrasive particles, higher temperature), option to migrate to more wear-resistant materials or enhanced barrier-fluid plans.

- Preventive-maintenance programmes: periodic inspections, condition-based monitoring, performance trending, and reliability assessments — to maximize mean time between maintenance (MTBM), reduce unplanned shutdowns, and lower total lifecycle cost of seal ownership.

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049