Single Cartridge Seal SPW131 – High-Performance Mechanical Seal

Single Cartridge Seal SPW131 – High-Performance Mechanical Seal

Overview

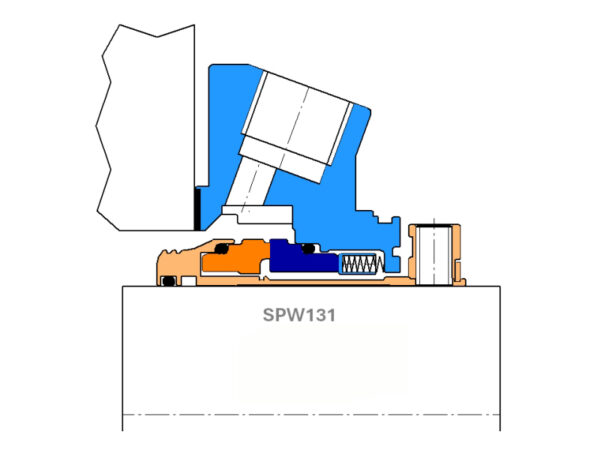

HydroMax Seal SPW131 | Compact Single Cartridge Seal for Plan 31 with Vortex Breakers

The SPW131 is a single-cartridge mechanical seal designed with integral vortex breakers in the gland plate, optimized to fit into compact, small cross-sectional seal chambers. Built in accordance with API610 Ed.5 onwards, this seal is ideal for process fluids containing suspended particles and solids, and is engineered for API Plan 31 piping arrangements.

This stationary cartridge seal is a complete, factory-assembled solution that delivers enhanced reliability and wear resistance in challenging process environments.

Product Description

Design Features

- Flush orifice for Plan 31 ensures that flush fluid containing solids does not “shot-blast” the stationary seal face

- Large 1/2″ NPT seal port orifices for efficient fluid flow

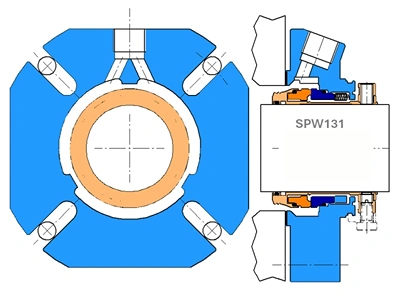

- Gland plate with integrated vortex breakers—prevents particle recirculation and optimizes seal chamber hydraulics

- Compact cartridge design with short inboard and outboard lengths

- Designed for small cross-sectional seal chambers as per API610 requirements

- Multi-spring configuration with springs positioned outside the process fluid

- Hydraulically balanced seal face design enhances pressure handling capability

- Monolithic seal faces improve performance in high-temperature operations

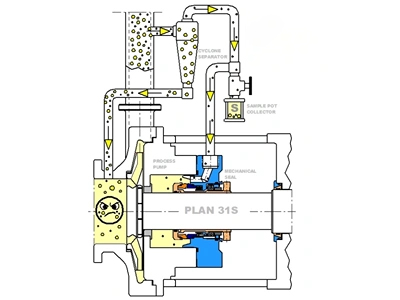

- Fully compatible with HydroMax Plan 31 Cyclone Separator and Sample Collection Pot systems

Technical Specifications

| Seal Shaft Sizes | All |

| Inboard Seal Face Combination | TC / TC Car / TC Ant. Car / RB SiC |

| Gasket | Spiral Wound Stainless Steel, Graphite |

| Secondary Sealing | Viton, Alfas, ERP, Kalrez |

| Shaft Speeds | Up to 4,000 rpm |

| Pressures | Up to 25 Barg |

| Instrumentation | Used with Plan 31 piping systems |

| Temperatures | Up to 150°C |

The SPW131 is an API-compliant, best-practice stationary cartridge seal, purpose-built for solids-handling applications and engineered to provide extended seal life and stable operation in abrasive service conditions.

Typical Applications & Industry Use Cases

The SPW131 Single Cartridge Mechanical Seal is a compact, high-performance cartridge seal engineered for API Plan 31 piping arrangements. It features integral vortex breakers within the gland plate to improve seal chamber hydraulics and solids handling, making it well-suited for process fluids containing suspended particles or abrasives. Its compact construction allows installation in small cross-section seal chambers while maintaining reliable sealing performance.

Industries Served

Chemical processing

Water and wastewater treatment

Petrochemical and refinery services

Power generation and utility pumping

General industrial fluid handling

OEM and engineered equipment applications

Equipment & Use-Case Scenarios

- Single-seal cartridge installations using API Plan 31 flush systems

- Services involving fluids with solids or particulates require improved seal chamber hydraulics

- Pumps and rotating equipment with limited gland space

- Applications where reduced maintenance and high reliability are required

Why It Fits These Applications

- Plan 31 optimized flush orifice: Directs flush fluid away from the stationary seal face, reducing abrasive impact

- Integral vortex breakers: Minimise turbulence and improve management of suspended solids in the seal chamber

- Compact cartridge design: Fits smaller seal cavities without compromising sealing performance

- Hydraulically balanced face design: Improves pressure capability and operating stability

- Multi-spring configuration: Provides uniform seal face loading and isolates springs from the process fluid

- Monolithic seal faces: Enhance wear resistance and performance in elevated-temperature services

Installation Guidelines

Pre-Installation Preparation

Thoroughly clean and inspect the pump shaft, seal chamber bore, and gland face. Remove corrosion, debris, or surface damage to ensure accurate alignment and proper seal face contact.

Seal Installation

Install the SPW131 cartridge seal into the seal housing, ensuring the flush orifice and vortex breaker are correctly oriented according to the API Plan 31 piping arrangement. Secure the cartridge evenly to the recommended torque values.

Alignment & Fit

Verify that the stationary seat and rotating seal faces are properly aligned within the housing to maintain consistent contact during operation.

Startup Procedure

Start flush fluid circulation before bringing the equipment to operating speed and pressure. Monitor the seal area for leakage, vibration, or abnormal temperature rise during initial operation.

Maintenance & Inspection Best Practices

- Routine Visual Inspections: Check the seal area regularly for leakage, vibration, or excessive heat

- Seal Face Examination: During scheduled shutdowns, inspect faces for wear, scoring, or deposits

- Vortex Breaker Monitoring: Inspect for solids buildup or erosion that could restrict flow

- Operational Records: Log pressure, temperature, and shaft speed data to support predictive maintenance

- Spare Parts Availability: Keep replacement O-rings, springs, seal faces, and cartridge components on hand

Service & Support Options

- Application Review: Confirm seal materials and configuration align with fluid chemistry and operating conditions

- Installation Support: Technical assistance to ensure correct installation and reliable first-run performance

- Preventive Maintenance Planning: Establish inspection and replacement schedules based on service severity

- Seal Upgrade Evaluation: Consider alternative materials or designs if process conditions become more demanding

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049