Multi-Spring Seal IPW-021 – High-Performance Cartridge Design

Multi-Spring Seal IPW-021 – High-Performance Cartridge Design

Overview

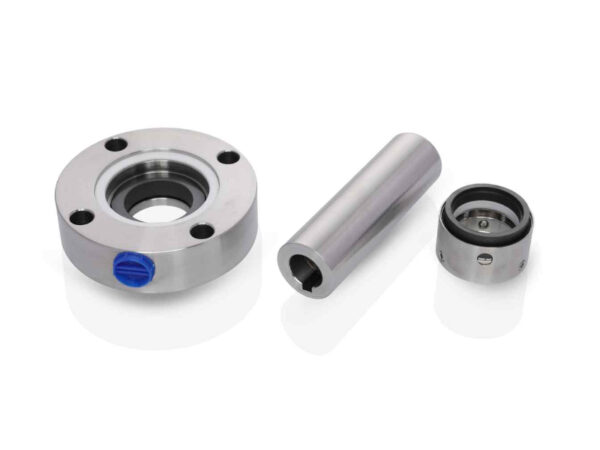

The IPW-021 is a MULTI SPRING SEAL ASSEMBLY WITH PTFE WEDGE PACKING.

Internal Wet Seal, Monolithic Rotary Head, Parallel shaft Wedge Packing, Multi-Spring & Set Screw Driven (Standard w/length).

The seal can be supplied with gland plate, stationary, and equipment sleeve, as shown, to suit the equipment/application.

The seal has a number of design features and is dimensionally interchangeable with JC Type 9 component seal. It is supplied with a stationary seat as standard.

Product Description

Technical Specifications

| Seal Shaft Sizes | 12mm – 100mm (1.000″ – 4.000″) |

| Inboard Seal Face Combination | Car/TC and Car/SiC |

| Secondary Sealing | PTFE |

| Shaft Speeds | Up to 20 m/s |

| Pressures | Up to 5 barg (72 psig) – shaft size specific |

Typical Applications & Industry Use Cases

The IPW-021 is a multi-spring internal-wet mechanical seal with a monolithic rotary head and PTFE wedge packing. It is designed for parallel-shaft rotating equipment and is well-suited for clean or moderately demanding fluid services that require reliable internal wet sealing.

Industries Served

Water supply and utility pumps handling clean or lightly contaminated fluids.

Light to medium chemical processing applications that require PTFE chemical resistance.

General industrial fluid-handling systems under moderate pressure and temperature.

OEM and maintenance/retrofit applications needing a compact, easy-to-install replacement seal.

Equipment & Use-Case Scenarios

- Centrifugal and horizontal pumps with shaft diameters from 12 mm to 100 mm.

- Applications operating at shaft speeds up to approximately 20 m/s and moderate pressures.

- Pumps requiring a PTFE wedge secondary seal for improved chemical compatibility.

- Situations where a dimensional replacement for common component-seal standards (such as Type 9) is required.

Why It Fits These Applications

- Multi-spring design ensures uniform face loading and stable sealing performance.

- Monolithic rotary head and PTFE wedge packing improve chemical resistance and durability.

- Interchangeable dimensions make it an excellent retrofit choice with minimal pump modification.

- Compact internal-wet design makes it suitable for a wide range of general-purpose industrial pumps.

Installation Guidelines

Clean the shaft, seal chamber, and gland surfaces thoroughly before installation.

Install the IPW-021 carefully, ensuring the PTFE wedge packing and set-screw drive are properly seated.

Verify that all operating conditions — pressure, speed, temperature, and fluid chemistry — match the seal’s ratings.

Perform a controlled startup and monitor for leaks, temperature rise, or abnormal vibration.

Maintenance & Inspection Best Practices

- Inspect seal faces and mating surfaces during scheduled maintenance shutdowns.

- Check the condition of the PTFE wedge packing, springs, and set-screw drive components.

- Track operating hours, cycling frequency, fluid characteristics, and any operational deviations.

- Increase inspection frequency if the pump handles more aggressive fluids or runs at higher pressures.

- Ensure shaft alignment and surface finish remain within tolerance to maintain optimal seal life.

Service & Support Options

- Pre-installation reviews to validate suitability for the operating environment.

- Availability of spare parts, including stationary seats, rotary heads, and PTFE wedges.

- Support during commissioning — alignment checks, leak testing, and startup validation.

- Preventive maintenance programs tailored to operating conditions and duty cycles.

- Recommendations for upgrades or alternative seal configurations if operating conditions become more demanding.

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049