Labyrinth HydroMax Seal LAB-100 – High-Performance Shaft Seal

Labyrinth HydroMax Seal LAB-100 – High-Performance Shaft Seal

Overview

HydroMax Seal LAB-100 | High-Performance IP69K Labyrinth Seal for Bearing Protection

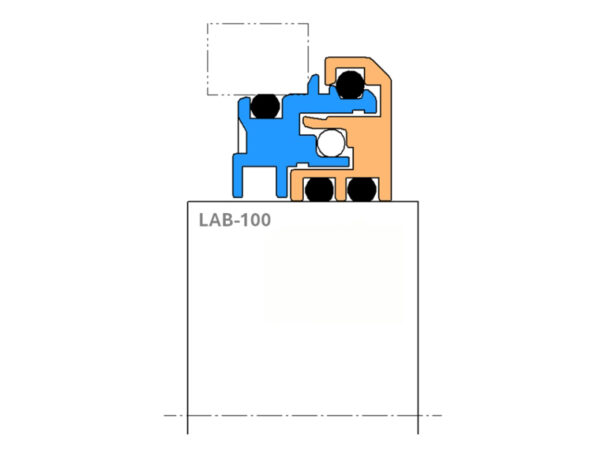

The LAB-100 is a high-performance Labyrinth Seal certified to IP69K, providing premium protection for rotating equipment bearing chambers in demanding environments.

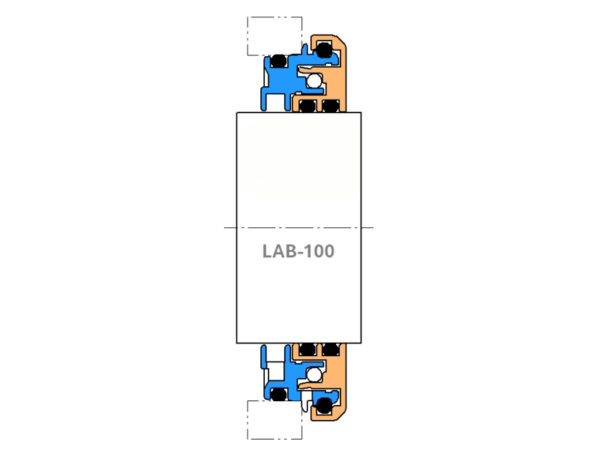

Designed to fit small cross-sectional spaces, this seal is a direct replacement for traditional lip or oil seals. The LAB-100 is offered as a complete cartridge solution, and it is installed similarly to conventional sealing elements for ease of use.

Product Description

Design Features

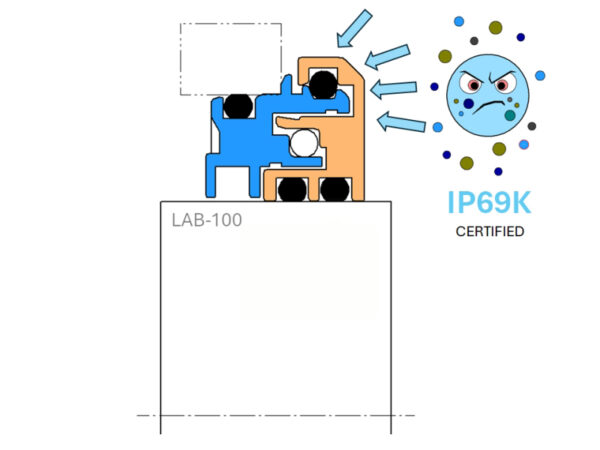

- IP69K certified – protects against dust, high temperature, and high-pressure water ingress

- Cartridge-style, one-piece construction ensures simple and secure installation

- Bi-metallic construction – optimizes operational durability and thermal stability

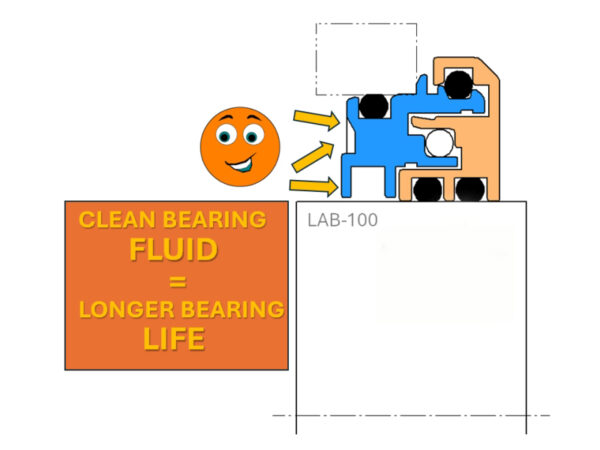

- Inboard orifice – repels oil and bearing fluid

- Outboard orifice – repels water and dust

- Integral PTFE barrier seal – enhances chemical and thermal resistance

- Twin rotor O-ring drive – stabilizes rotor, enabling minimal radial clearance between rotor and stator for better sealing

- Compact form factor – compatible with most rotating equipment rotor/stator housings

Technical Specifications

| Seal Shaft Sizes | All |

| Secondary Sealing | Viton Alfas ERP Kalrez PTFE |

| Shaft Speeds | Up to 4,000 rpm |

| Pressures | — |

| Temperatures | Up to 302°F |

This innovative LAB-100 labyrinth seal incorporates industry best practices for performance and hygiene. Visit our Blog section for technical white papers and insights into the design principles behind this product.

Typical Applications & Industry Use Cases

The LAB-100 Labyrinth Seal is a high-performance, non-contact shaft sealing solution designed to protect rotating equipment bearing chambers from contaminants while retaining lubrication. Certified to IP69K, it offers exceptional resistance to dust, high-pressure water jets, and high-temperature washdown, making it suitable for demanding industrial and sanitary applications.

Unlike contact-type seals, the labyrinth design uses a series of engineered flow paths and repellent orifices to restrict contaminant ingress without metal-to-metal contact. This non-contact operation minimizes wear, reduces friction, and enables extended service life.

Industries Served

Water and wastewater treatment

Food and beverage processing and washdown environments

Chemical and petrochemical plants

Pharmaceutical and biotechnology manufacturing

Heavy industrial rotating equipment

Utilities and manufacturing facilities requiring robust bearing protection

Equipment & Use-Case Scenarios

- Rotating equipment where traditional lip or oil seals are replaced with a longer-lasting, maintenance-free solution

- Bearing housings exposed to dust, moisture, chemicals, or frequent washdowns

- Equipment operating in high-pressure or high-temperature cleaning environments

- Applications where reducing maintenance and extending bearing life are critical

Why It Fits These Applications

- IP69K-rated protection: Withstands high-pressure, high-temperature washdowns and severe contamination

- Non-contact labyrinth design: Eliminates wear and friction associated with traditional contact seals

- Inboard repellent orifice: Helps retain bearing lubrication inside the housing

- Outboard contaminant repellent orifice: Deflects water, dust, and external contaminants

- Integral PTFE barrier seal: Enhances chemical resistance and thermal stability

- Twin rotor O-ring drive: Maintains stable rotor positioning and tight radial clearances

- Compact construction: Fits into housings originally designed for standard oil or lip seals

Installation Guidelines

Pre-Installation Preparation

Ensure the shaft and bearing housing bore are clean, smooth, and free of corrosion or debris. Verify the dimensions to ensure the intended radial clearance is maintained.

Seal Installation

Install the LAB-100 labyrinth seal as a complete assembly into the bearing housing. Confirm correct orientation so the inboard and outboard repellent features align properly with the bearing chamber and external environment.

Alignment & Fit

Check for proper seating and concentric alignment. The twin-rotor O-ring drive helps maintain stability and reduces the risk of runout during operation.

Operational Readiness

Run the equipment at low speed initially and observe bearing temperatures and vibration. Proper installation should result in smooth operation with no abnormal heat or noise.

Maintenance & Inspection Best Practices

- Routine Visual Inspections: Check for signs of lubricant leakage or contaminant ingress

- Bearing Condition Monitoring: Track bearing temperature and vibration trends

- Washdown Monitoring: Ensure seal pathways remain clear in high-washdown environments

- Operating Logs: Maintain records of speed, temperature, and environmental exposure

- Seal Replacement: Replace components if PTFE or elastomer elements show cracking, deformation, or excessive wear

Service & Support Options

- Application Review: Confirm material compatibility and suitability for the operating environment

- Installation Assistance: Guidance to ensure correct fit and orientation

- Preventive Maintenance Planning: Inspection intervals based on operating severity

- Sealing Upgrades:Evaluate alternative or enhanced sealing solutions if environmental conditions intensify

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049