HydroMax Seal SPW682-53 – Multi-Spring Industrial Pump Seal

HydroMax Seal SPW682-53 – Multi-Spring Industrial Pump Seal

Overview

Double Cartridge Mechanical Seal for API Plan 53 Systems

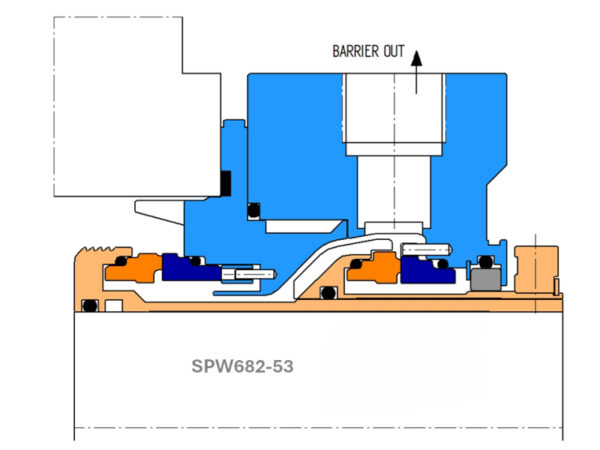

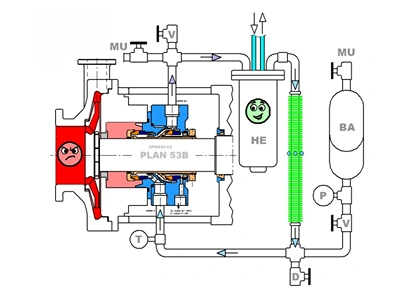

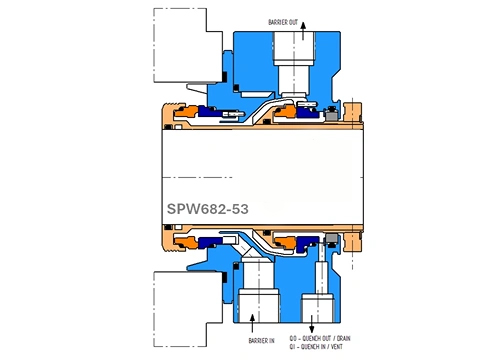

The SPW682-53 from HydroMax Seal is a high-performance double cartridge mechanical seal, fully designed in accordance with API682 standards, and engineered for mission-critical Oil & Gas applications. Developed for use with API Plan 53A, 53B, and 53C configurations on API610 V8 and newer process pumps, this seal ensures superior containment, cooling, and pressure control.

This advanced stationary seal assembly incorporates a bi-directional barrier fluid pumping ring and is suitable for slurry, high-speed, or high-temperature applications.

Product Description

Design Features

- 1/2″ NPT Barrier Fluid In (BI) and Out (BO) orifices for efficient flow in Plan 53 or 52 systems

- Barrier fluid deflector integrated into the gland plate — ensures directed fluid flow to inboard faces and thermal removal from outboard seal faces

- Quench (Vent) and Drain orifices for Plan 62 compatibility — includes outboard floating restriction bush to maintain seal integrity upon primary seal failure

- Integrated vortex breakers in the gland for handling slurries and process fluids with solids

- API682-compliant radial clearances between rotating and stationary elements for operational stability

- Monolithic seal faces are designed to withstand elevated temperatures

- Stationary self-aligning seal face is ideal for high-speed operations

- Multi-spring configuration — springs are positioned outside the process fluid for enhanced durability

- High-efficiency bi-directional pumping ring for barrier fluid circulation in pressurized dual seal systems

- Fully compatible with HydroMax Seal’s Plan 53A/B/C support systems, including heat exchangers, reservoirs, and flow controls

Technical Specifications

| Seal Shaft Sizes | All standard and custom options available |

| System Vessel Sizes | 3.17 gallons and 7.40 gallons |

| Inboard Seal Face Combinations | TC / TC Carbon / TC Antimony Carbon / RB SiC Antimony Carbon / TC RB SiC / RB SiC |

| Outboard Seal Face Combinations | Carbon / TC Carbon / RB SiC Antimony Carbon / RB SiC Antimony Carbon / TC |

| Gasket Material | Spiral Wound Stainless Steel with Graphite |

| Secondary Sealing Materials | Viton, Alfas, ERP, Kalrez |

| Maximum Shaft Speed | Up to 4,000 RPM |

| Maximum Pressure Rating | Up to 40 Barg |

| Instrumentation | Designed for full integration with Plan 53 systems |

| Operating Temperature | Up to 482°F |

The SPW682-53 is part of HydroMax Seal’s premium mechanical seal lineup, engineered with API682 best practices for reliability, safety, and performance. Ideal for critical service applications, this seal offers dependable operation even in the harshest environments.

Typical Applications & Industry Use Cases

The SPW682-53 is a double-cartridge mechanical seal designed for high-duty process environments and meets the rigorous requirements of API 682. Featuring an integrated bi-directional barrier-fluid pumping ring, large port orifices, a self-aligning stationary seal design, and a vortex-breaker gland plate, this seal is engineered for demanding rotary-shaft installations in oil & gas, refining, and petrochemical plants.

Industries Served

Oil & gas

process pumps in refineries, gas production, and petrochemical plants where dual seals and barrier fluid support are essential.

Petrochemical & chemical processing

aggressive media, high pressure, high temperature applications where seal integrity and reliability are non-negotiable.

Utility and power generation

large centrifugal pumps, feed pumps, or auxiliary systems requiring API-rated sealing solutions.

Heavy industry

large-shaft rotating equipment where cartridge ease, high speed capability, and tight face control are required.

Equipment & Use-Case Scenarios

- Process pumps installed to API 610 (version 8 and higher), where a dual-seal, barrier-fluid design (Plan 53A/53B/53C) is applied.

- High-speed or high-temperature services (e.g., up to ~4,000 rpm and ~250 °C) require a self-aligning stationary face construction and robust materials.

- Systems with solid or particulate-laden media where the gland plate’s vortex-breaker design assists in managing turbulence and debris.

- Pump systems that require large barrier-fluid tubular ports and efficient heat removal in the barrier loop to maintain face lubrication and control leakage.

Why It Fits These Applications

- Its large half-inch NPT barrier fluid ports improve flow capacity in Plan 53 or Plan 52 loops, enhancing cooling and barrier fluid circulation.

- The integrated deflector within the barrier fluid path directs flow over inboard seal faces, while the outlet covers outboard faces for effective heat removal on both sides.

- Self-aligning stationary face design supports high shaft speeds and reduces sensitivity to minor misalignment or thermal expansion.

- A gland plate with integral vortex breakers helps in applications with solids or suspended particles, reducing risks of seal face damage from swirl or debris.

- Cartridge-style assembly simplifies installation and replacement in large process pumps, enhancing uptime and reducing maintenance effort.

Installation Guidelines

Start by thoroughly cleaning the pump shaft, seal chamber bore, and gland face. Confirm alignment, remove scoring or deposits, and verify mechanical tolerances.

Slide the SPW682-53 cartridge into place without forcing components; ensure proper orientation of barrier fluid in- and out-ports, quench/vent ports (if applicable), and that the set-screw drive is engaged correctly.

Connect the barrier fluid piping in accordance with your Plan 53A/53B/53C layout, ensuring that the supply and return lines, venting, filtration, and heat-exchanger equipment are properly installed and commissioned.

Before putting the pump into full service, bring up barrier fluid circulation, verify flow/pressure, and ensure the fluid is clean. Temperature is within expected limits, then initiate pump rotation under load.

Record baseline data: barrier fluid pressure, flow, temperature, seal face temperature, and any vibration or shaft run-out readings. This baseline supports future condition monitoring.

Maintenance & Inspection Best Practices

- Regularly monitor barrier fluid loop parameters: incoming/outgoing fluid temperatures, flow rate, pressure drop across filters, and any signs of contamination or degradation. A drop in performance may indicate seal wear or loop restriction.

- During planned shutdowns, if feasible, remove the cartridge to inspect seal faces (for scoring and wear patterns), O-rings/gaskets, springs, and the pumping ring condition.

- Keep an operational log with details such as shaft speed, fluid chemistry changes, temperature/pressure excursions, start-stop cycles, and any maintenance actions. Historical data will help predict service intervals and prevent unplanned downtime.

- Refresh secondary seals (O-rings, gaskets) and inspect barrier fluid quality at regular intervals. Ensure filter elements are replaced or cleaned as required to maintain barrier loop performance.

- If service conditions evolve—e.g., higher temperature, increased solids, higher speed, more corrosive media—review whether the SPW682-53 still meets the application or if an upgrade in materials or support plan is necessary.

Service & Support Options

- Pre-installation technical review: assistance is available to verify appropriate seal face materials (e.g., SiC, WC, TC combinations), elastomer selection, and barrier fluid support scheme for your specific application.

- Field or remote commissioning support typically includes verification of barrier-fluid loop activation, measurement of seal-face temperature under load, and performance validation.

- Spare-parts kits tailored to the SPW682-53 cartridge: includes seal faces, O-rings/gaskets, springs, pumping ring components, set screws, and hardware—optimised for reduced downtime.

- Upgrade services: as service demands increase (speed, pressure, temperature, media complexity), options exist to migrate to more advanced materials or enhanced support-system designs.

- Preventive maintenance programmes: scheduled inspections, performance tracking, condition-based alerts, and reliability reviews to increase the mean time between maintenance, reduce the total cost of ownership, and improve equipment uptime.

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049