Double Cartridge Seal SPW-516 – Durable Industrial Mechanical Seal

Double Cartridge Seal SPW-516 – Durable Industrial Mechanical Seal

Overview

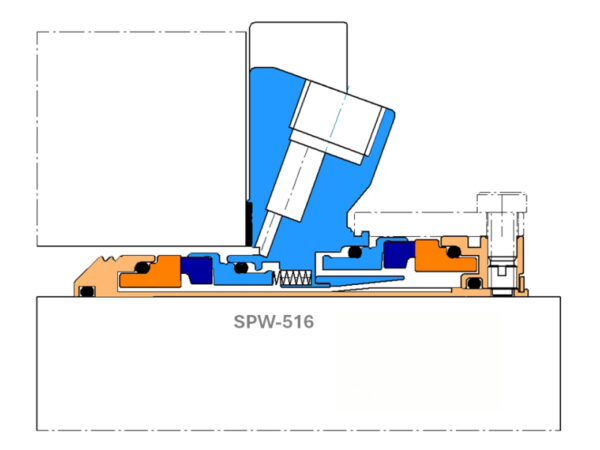

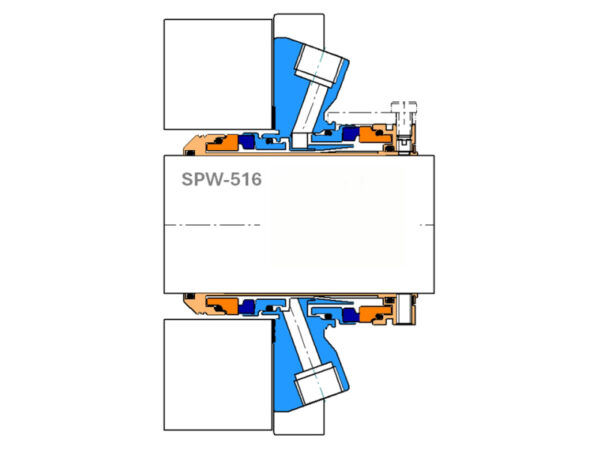

HydroMax Seal SPW-516 | Double Cartridge Stationary Seal with Integral Flow Inducer

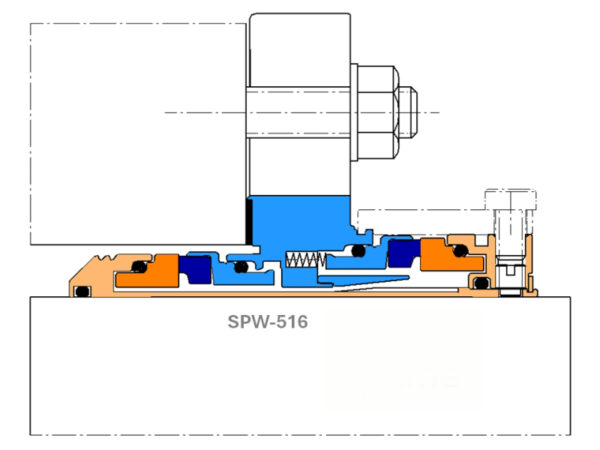

The SPW-516 is a multi-spring, hydraulically balanced double cartridge stationary seal featuring an integral flow inducer, barrier fluid quench & drain ports, and O-ring secondary seals.

This Stationary Pusher Wet (SPW) Double Cartridge Seal includes shrink-fitted seal faces and is designed for use with parallel rotating equipment shafts.

With advanced design features such as directed barrier fluid flow and self-aligning seal faces, the SPW-516 ensures optimal heat removal and reliability in demanding applications. The cartridge design simplifies installation with pre-set seal faces, eliminating the risk of incorrect face load settings. It includes Quench, Drain, and Flush ports as standard.

Factory assembled and tested, the SPW-516 is suitable for use with seal support systems and compatible with Plan 52 and Plan 53 configurations.

Product Description

Design Features

- Stationary seal with self-aligning seal faces to accommodate angular misalignment

- The Integral Flow Inducer ensures efficient, directed barrier fluid flow across seal faces

- Large 3/8″ NPT port connections

- Cartridge design with pre-set seal faces for easy installation and consistent performance

- Quench, Drain, and Flush port connections included as standard

- A wide range of seal face materials is available for diverse applications

Technical Specifications

| Seal Shaft Sizes | 20mm – 150mm (1.000″ – 6.000″) |

| Inboard Seal Face Combinations | Car/TC Car/SiC TC/TC TC/SiC SiC/SiC |

| Outboard Seal Face Combinations | Car/TC Car/SiC |

| Gasket | GFT |

| Elastomers | Viton ERP Aflas Kalrez |

| Shaft Speeds | Up to 20 m/s |

| Pressures | Up to 290.1 psig (process fluid) 16 barg (232 psig) barrier fluid – Shaft Size Specific |

| Pipework & Fittings | Plan 52 and Plan 53 |

| Temperatures | Up to 356°F |

WARNING:

The safe seal performance characteristics are typical values for each variable in isolation. The individual upper limit values of speed, pressure, and temperature should NOT be used in combination.

Typical Applications & Industry Use Cases

The SPW-516 Double Cartridge Seal is a hydraulically balanced, multi-spring double-cartridge mechanical seal designed for use on parallel-shaft rotating equipment that requires robust sealing performance, controlled support-fluid circulation, and enhanced reliability. With dedicated ports for flush, quench, and drain, the SPW-516 supports a range of seal-support fluid plans, helping to maintain stable seal-face lubrication, heat dissipation, and contamination control.

Industries Served

Chemical processing and petrochemical facilities

Refining and hydrocarbon transfer systems

Water and wastewater treatment plants

Power generation utilities and auxiliary equipment

General industrial pumping and rotating machinery

Equipment & Use-Case Scenarios

- Parallel-shaft centrifugal and process pumps needing dual-seal arrangements with external support-fluid loops

- Services with variable pressure or temperature, where balanced faces and support-fluid flow improve stability

- Systems requiring controlled flush or quench fluid circulation to remove heat and particulates from seal faces

- Installations where cartridge-style seals reduce installation time and minimise the risk of assembly error

Why It Fits These Applications

- Balanced, multi-spring design ensures even face loading across a range of operating conditions, improving reliability and wear resistance.

- Integrated quench, flush, and drain ports support connection to external support-fluid plans that enhance cooling, lubrication, and contaminant flushing.

- Double-seal construction improves containment of process fluids and reduces the risk of leakage in critical or safety-sensitive services.

- Cartridge assembly simplifies installation and maintenance, reducing downtime and the risk of misalignment compared with component-style seals.

Installation Guidelines

Surface Preparation

Before installation, thoroughly clean and inspect the pump shaft, seal chamber bore, and gland face. Remove any corrosion, scoring, debris, or surface defects to ensure smooth, accurate sealing and proper face alignment.

Cartridge Installation

Carefully slide the SPW-516 double cartridge into the gland or seal chamber. Confirm the correct orientation of the quench, flush, and drain ports in accordance with your external support-fluid piping plan.

Support-Fluid Connections

Attach quench, flush, and barrier/buffer fluid lines as required by your support-fluid plan. Prime and vent all loops to remove air and confirm fluid flow before startup.

Controlled Startup

Begin with support-fluid circulation, verify stable flow and pressure, and then bring the equipment up under monitored conditions. Observe seal-face temperature, support-fluid parameters, and overall vibration or leakage before progressing to full duty.

Maintenance & Inspection Best Practices

- Monitor Support Fluids: Routinely check flow rates, pressures, and temperatures in quench, flush, and barrier loops. Changes in these parameters can indicate restrictions, contamination, or early wear.

- Scheduled Inspections: During planned shutdowns, inspect the cartridge assembly for wear or damage; check the seal faces, springs, secondary seals, and gland surfaces for abrasion, deposits, or corrosion.

- Operational Logging: Maintain a detailed record of operating conditions, including fluid properties, shaft speeds, pressures, and temperature cycles. Use this information to predict maintenance needs and optimise servicing intervals.

- Replace Consumables Preventively: Refresh secondary seals (O-rings, gaskets) and support-fluid filters at scheduled intervals, rather than waiting for failure, to help extend overall service life.

- Service Condition Changes: If process conditions change — such as higher speeds, temperatures, or more aggressive fluids — reassess face materials, elastomer compatibility, and support-fluid plans to maintain performance and reliability.

Service & Support Options

- Application Review: Verify that the chosen materials and support-fluid plan are appropriate for your fluid chemistry, temperature, and pressure conditions to optimise life and performance.

- Spare Parts Availability: Maintain stocks of replacement seal faces, secondary seals, springs, and cartridge hardware to minimise maintenance downtime.

- Installation Assistance: Technical support for alignment, port orientation, and monitored commissioning can help ensure correct first-run performance.

- Preventive-Maintenance Planning: Establish periodic inspection and replacement schedules based on operational history to maximise mean time between maintenance and reduce unexpected failures.

- Upgrade Guidance: If service requirements intensify (e.g., higher speeds, more aggressive fluids, or elevated temperatures), evaluate alternative materials or enhanced seal designs to meet the new demands.

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049