High-Efficiency SPS-625 Double Cartridge Seal for Pumps

High-Efficiency SPS-625 Double Cartridge Seal for Pumps

Overview

HydroMax Seal SPS-625 | Heavy-Duty Double Cartridge Mechanical Seal for Slurry Applications

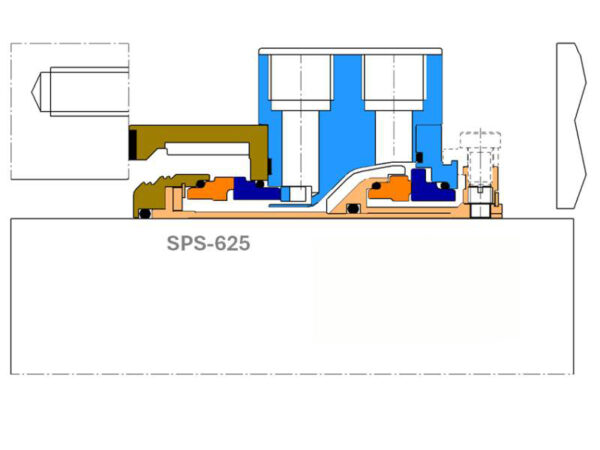

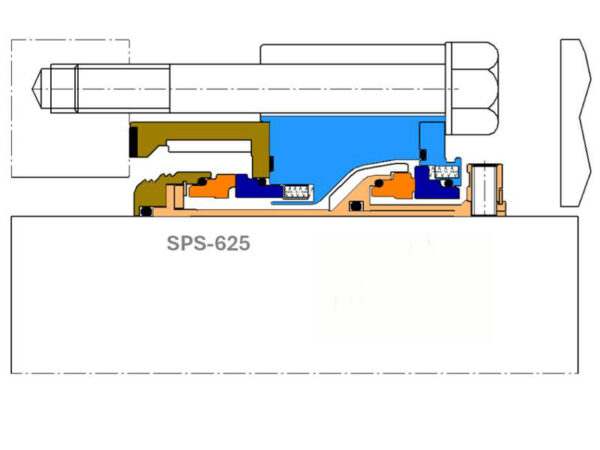

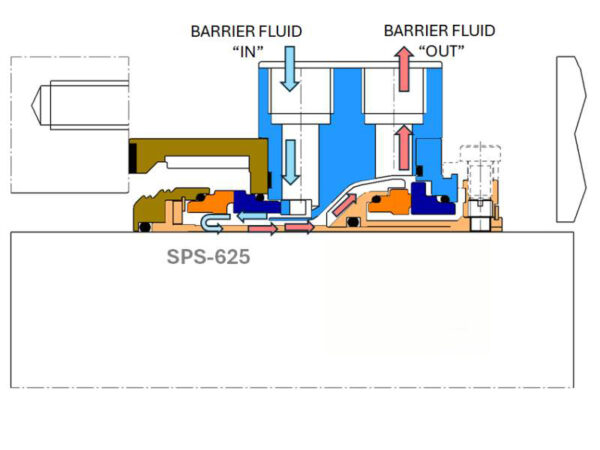

The SPS-625 is a double cartridge mechanical seal with an integral, bi-directional barrier fluid pumping ring and wear-resistant inboard wetted parts. Engineered for heavy-duty slurry applications, it is ideal for handling particle-laden process fluids in Mining & Mineral, Pulp & Paper, and Water & Waste industries.

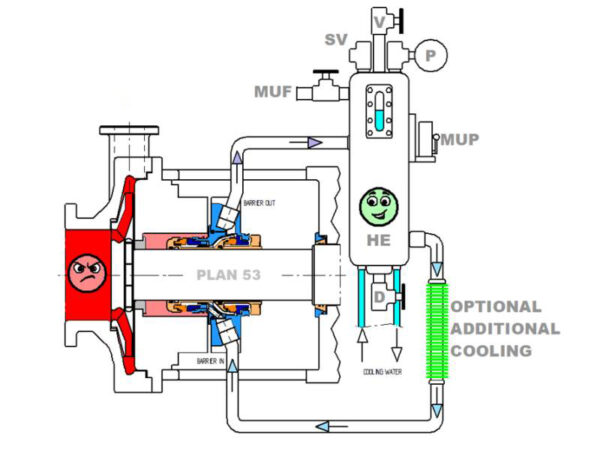

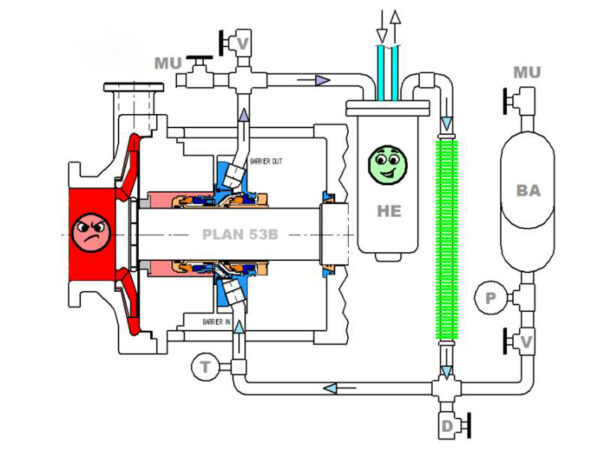

This stationary seal design is delivered as a complete cartridge mechanical seal solution and is compatible with Plan 53, 53A, 53B, and 53C system piping arrangements.

In equipment with a small cross-section seal chamber, the SPS-625 can be fully mounted externally (space permitting). The gland insert with integral vortex breakers ensures an optimal fluid environment over the inboard seal faces for enhanced durability and performance.

Product Description

Design Features

- Sleeve end cap and gland insert available in wear-resistant materials to match severe slurry service

- Fully outboard mounted design for compact seal chambers/stuffing boxes prone to premature seal wear

- Large 1/2″ NPT Barrier Fluid In (BI) and Barrier Fluid Out (BO) orifices for Plan 53 or 52 systems

- Integrated deflector in seal gland directs fluid to inboard faces; outboard fluid exit ensures effective thermal management

- Gland insert with vortex breakers enhances performance in solid-laden process media

- Radial clearances conform to API682 best practice standards

- Monolithic seal faces for reliable high-temperature service

- Stationary design with self-aligning seal face, ideal for high-speed operation

- Multi-spring arrangement with springs located outside the process fluid

- Highly efficient bi-directional barrier fluid pumping ring

- Designed for use with HydroMax Seal Plan 53, 53A, 53B, and 53C Seal Support Systems

Technical Specifications

| Seal Shaft Sizes | All |

| System Vessel Size | 12L and 28L |

| Inboard Seal Face Combination | TC/TC Car/TC Ant.Car/RB SiC Ant.Car/TC RB SiC/RB SiC |

| Outboard Seal Face Combination | Car/TC Car/RB SiC Ant.Car/RB SiC Ant.Car/TC TC/TC |

| Gasket | Spiral Wound Stainless Steel, Graphite |

| Secondary Sealing | Viton, Alfas, ERP, Kalrez |

| Shaft Speeds | Up to 4,000 rpm |

| Pressures | Up to 25 Barg |

| Instrumentation | Used in conjunction with a Plan 53 piping system |

| Temperatures | Up to 250°C |

The SPS-625 is a high-performance, externally mountable stationary seal built for rugged slurry conditions and optimized for use in compact seal chambers with limited axial space.

Typical Applications & Industry Use Cases

The SPS-625 Double Cartridge Mechanical Seal is a heavy-duty, stationary double-seal assembly featuring an integral, bi-directional barrier-fluid pumping ring and highly wear-resistant, inboard wetted components. It is engineered for severe slurry services where fluids contain suspended solids or abrasive particles. The SPS-625 is supplied as a complete cartridge seal and is designed for use with Plan 53, 53A, 53B, and 53C barrier fluid support systems.

Industries Served

Mining and mineral processing

Pulp and paper manufacturing

Water and wastewater treatment

Heavy industrial slurry pumping

Abrasive fluid transport and handling

Equipment & Use-Case Scenarios

- Parallel-shaft pumps operating in slurry or abrasive services

- Applications requiring continuous barrier fluid circulation for seal face protection and heat removal

- Installations with limited seal chamber space where an externally mounted cartridge seal improves durability

- Systems utilizing Plan 53-series barrier fluid support loops to maximize seal life

Why It Fits These Applications

- Bi-directional barrier fluid pumping ring: Ensures effective circulation of barrier fluid to both inboard and outboard seal faces, improving cooling and lubrication

- Wear-resistant wetted components: Sleeve end caps and gland inserts are designed to withstand abrasive, particle-laden media.

- Integral vortex breakers: Create a stable fluid environment at the seal faces, reducing turbulence and particle impact

- API 682–compliant clearances: Radial clearances between rotating and stationary components follow industry best practices for reliability

- Cartridge-style construction: Simplifies installation, minimizes alignment errors, and supports straightforward integration with barrier fluid systems

Installation Guidelines

Pre-Installation Preparation

Thoroughly clean and inspect the pump shaft, seal chamber bore, and gland surfaces. Remove corrosion, debris, and surface imperfections to ensure accurate alignment and prevent premature wear.

Cartridge Installation

Install the SPS-625 cartridge seal into the seal housing. Confirm that barrier fluid ports and gasket surfaces are correctly oriented to match the selected Plan 53-series piping arrangement. Secure the cartridge according to the specified torque requirements.

Barrier Fluid Loop Setup

Connect barrier fluid inlet and outlet lines per the selected Plan 53, 53A, 53B, or 53C configuration. Prime and vent the barrier system to ensure continuous, air-free circulation before startup.

Controlled Startup

Initiate barrier fluid circulation first, then gradually bring the pump to operating conditions. Monitor seal temperature, vibration, and leakage during startup to confirm stable operation.

Maintenance & Inspection Best Practices

- Perform routine inspections for leakage, abnormal vibration, or elevated temperatures at the seal area

- Monitor barrier fluid pressure, flow rate, and cleanliness to detect restrictions or contamination

- Inspect inboard and outboard seal faces during scheduled maintenance for wear, scoring, or deposits

- Check vortex breaker and gland insert areas for erosion or solids buildup

- Maintain operating logs of pressure, temperature, and duty cycles to support predictive maintenance

Service & Support Options

- Application reviews to verify material compatibility and barrier fluid plan selection

- Installation and commissioning support to ensure correct seating and piping alignment

- Spare parts planning to reduce downtime during maintenance events

- Preventive maintenance scheduling based on service severity and operating history

- Evaluation of upgraded materials or configurations if abrasive content, temperature, or pressure increases

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049