Double Cartridge Seal SPS-610 – Durable Industrial Mechanical Seal

Double Cartridge Seal SPS-610 – Durable Industrial Mechanical Seal

Overview

HydroMax Seal SPS-610 | Double Cartridge Mechanical Seal for Slurry Applications

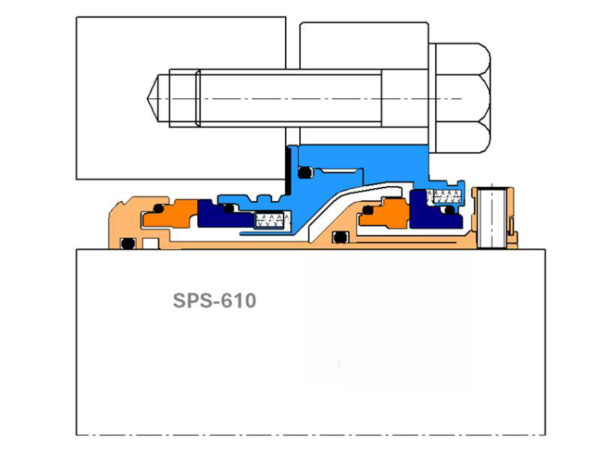

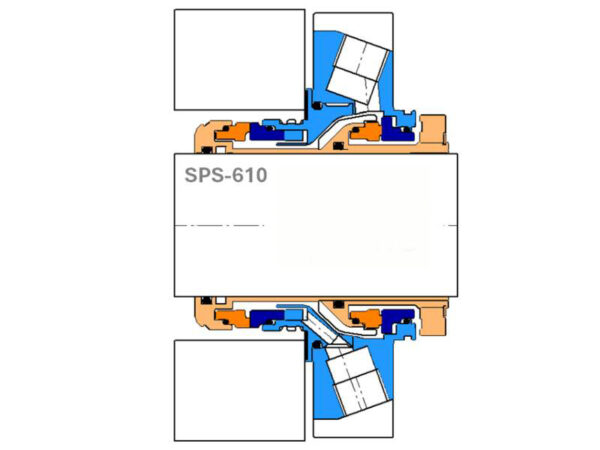

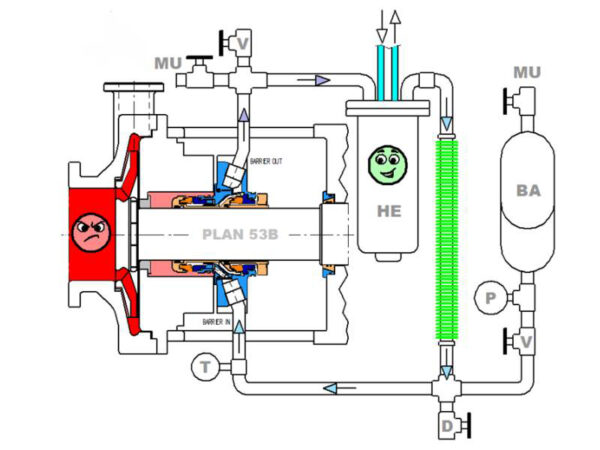

The SPS-610 is a double-cartridge mechanical seal featuring an integral, bi-directional barrier fluid pumping ring. Engineered for slurry service, it is ideal for handling process fluids with suspended particles in sectors such as Mining & Mineral, Pulp & Paper, and Water & Waste.

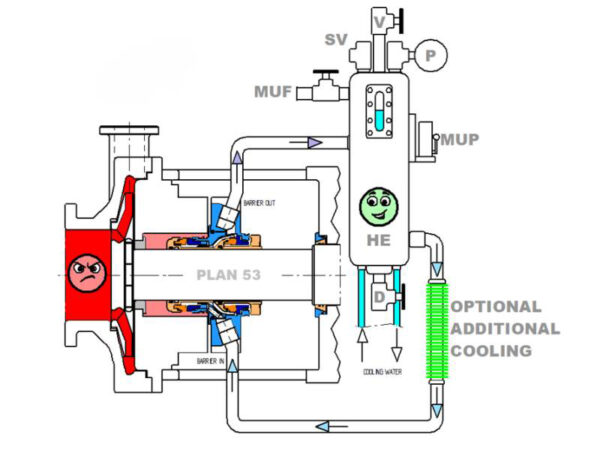

This innovative stationary seal design is supplied as a complete cartridge mechanical seal solution and is fully compatible with Plan 53, 53A, 53B, and 53C system piping arrangements.

Product Description

Design Features

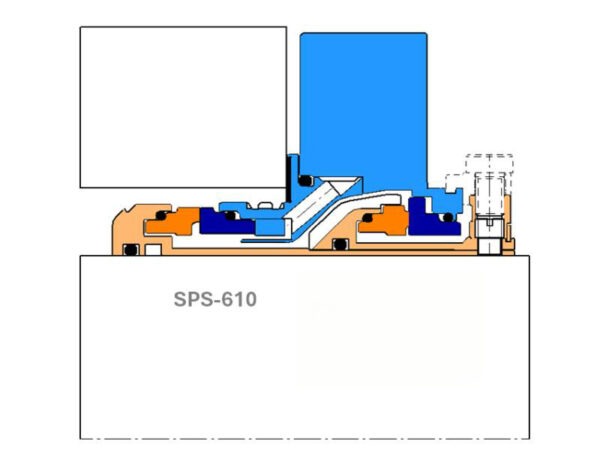

- Large 1/2″ NPT Barrier Fluid In (BI) and Barrier Fluid Out (BO) ports for Plan 53 or 52 systems

- Integrated deflector directs barrier fluid to inboard faces; outboard fluid exit provides efficient dual-face cooling

- Gland insert includes inboard vortex breakers for optimized performance in slurry and solid-laden media

- Radial clearances meet API 682 best practice standards

- Monolithic seal faces for enhanced high-temperature reliability

- Stationary seal configuration with self-aligning seal face—suited for high-speed applications

- Multi-spring design keeps springs out of process fluid for improved service life

- High-efficiency bi-directional barrier fluid pumping ring

- Designed for use with HydroMax Seal Plan 53, 53A, 53B, and 53C seal support systems

Technical Specifications

| Seal Shaft Sizes | All |

| System Vessel Size | 3.17 US gallons and 7.40 US gallons |

| Inboard Seal Face Combination | TC/TC, Car/TC, Ant.Car/RB SiC, Ant.Car/TC, RB SiC/RB SiC |

| Outboard Seal Face Combination | Car/TC, Car/RB SiC, Ant.Car/RB SiC, Ant.Car/TC, TC/TC |

| Gasket | Spiral Wound Stainless Steel, Graphite |

| Secondary Sealing | Viton, Alfas, ERP, Kalrez |

| Shaft Speeds | up to 4,000 rpm |

| Pressures | up to 362.6 psig |

| Instrumentation | Compatible with Plan 53 piping systems |

| Temperatures | up to 482°F |

The SPS-610 is a robust and compact stationary mechanical seal solution, specifically developed for slurry duties in standard thin cross-section seal chambers and stuffing box bores.

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049