Double Cartridge Seal SPS-625 – Durable Industrial Mechanical Seal

Double Cartridge Seal SPS-625 – Durable Industrial Mechanical Seal

Overview

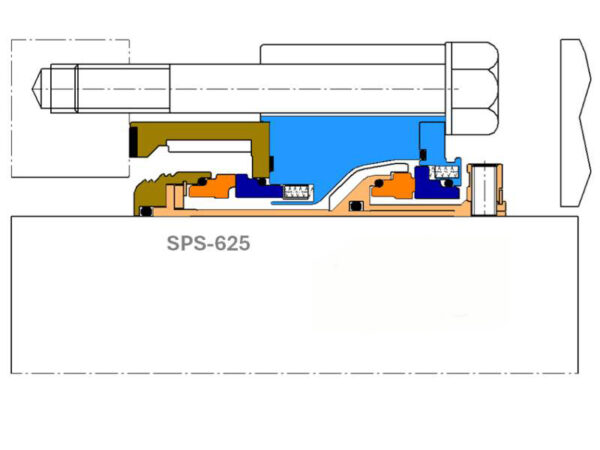

HydroMax Seal SPS-625 | Heavy-Duty Double Cartridge Seal for Slurry Applications with External Mounting Option

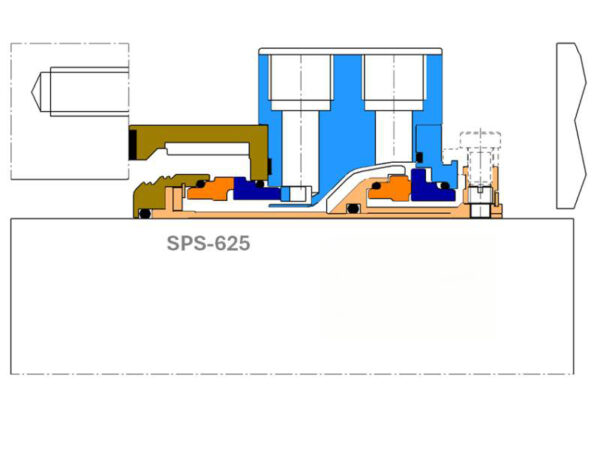

The SPS-625 is a double-cartridge mechanical seal designed for heavy-duty slurry applications in the mining and mineral, pulp and paper, and water and waste sectors. It features a bi-directional barrier fluid pumping ring and wear-resistant inboard wetted components, making it ideal for processing fluids with abrasive particles.

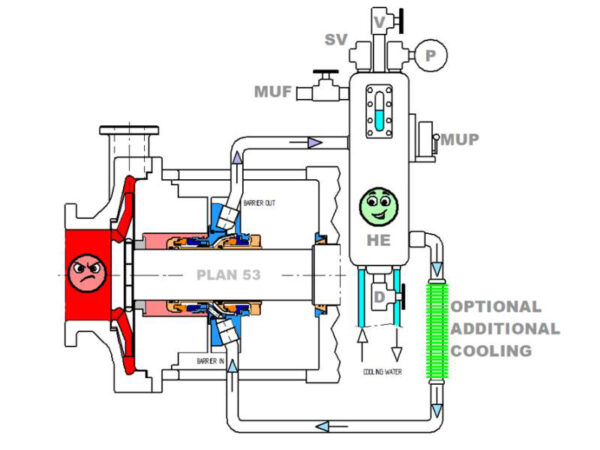

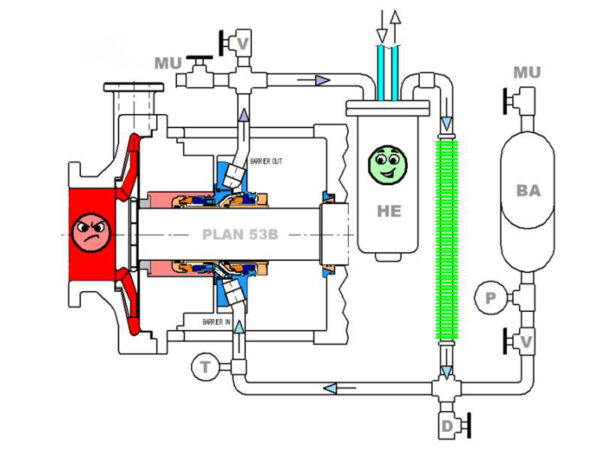

The stationary seal design is compatible with Plan 53, 53A, 53B, and 53C piping arrangements and can be fully mounted externally in equipment with limited space for the seal chamber, depending on the available clearance.

Product Description

Design Features

- Sleeve end cap and gland insert available in multiple wear-resistant materials

- External mounting option for equipment with small cross-section stuffing boxes

- 1/2″ NPT barrier fluid ports for Plan 53 or 52 compatibility

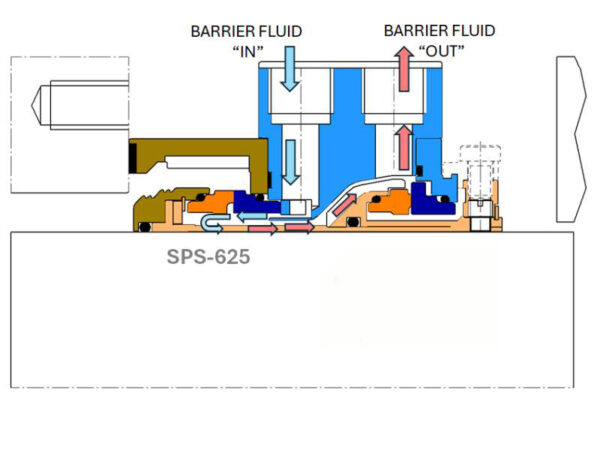

- The integral flow deflector directs cooling barrier fluid to the inboard and outboard seal faces

- Vortex breakers in the gland insert are ideal for slurry or solids-laden media

- API682-compliant radial clearances ensure mechanical integrity

- Monolithic seal faces for excellent temperature and pressure performance

- Self-aligning stationary seal face design for high-speed applications

- Multi-spring layout with springs isolated from process fluid

- High-efficiency bi-directional pumping ring supports optimal thermal regulation

- Compatible with Plan 53A, 53B, or 53C seal support systems

Technical Specifications

| Seal Shaft Sizes | All sizes supported |

| System Vessel Sizes | 3.17 US gallons and 7.40 US gallons |

| Inboard Seal Face Combinations | TC/TC, Car/TC, Ant.Car/RB SiC, Ant.Car/TC, RB SiC/RB SiC |

| Outboard Seal Face Combinations | Car/TC, Car/RB SiC, Ant.Car/RB SiC, Ant.Car/TC, TC/TC |

| Gasket Materials | Spiral Wound Stainless Steel, Graphite |

| Secondary Sealing Materials | Viton, Alfas, ERP, Kalrez |

| Shaft Speeds | Up to 4,000 rpm |

| Pressures | Up to 362.6 psig |

| Instrumentation | Designed for use with Plan 53 piping systems |

| Temperatures | Up to 482°F |

The HydroMax SPS-625 delivers exceptional durability and seal performance in abrasive, particle-laden processes, with flexibility for external mounting in compact equipment geometries.

Typical Applications & Industry Use Cases

The SPS-625 Double Cartridge Mechanical Seal is a heavy-duty sealing solution specifically engineered for abrasive, slurry, and solids-laden applications. Its robust double-seal configuration isolates the process fluid from the atmosphere via a pressurized barrier fluid, ensuring reliable operation in environments where conventional single-seal systems fail prematurely. The design prioritizes durability, thermal control, and protection of seal faces under extreme service conditions.

Industries Served

Mining and mineral processing

slurry transfer, tailings pumps, concentrate handling, and abrasive fluid movement.

Water and wastewater treatment

sludge handling, grit removal, solids-bearing effluent pumping.

Pulp and paper processing

pulp stock, fiber-laden fluids, and abrasive process streams.

Heavy industrial processing

chemical slurries, industrial byproducts, and high-wear fluid services.

Energy and power plants

ash handling, scrubber systems, and contaminated process fluids.

Equipment & Use-Case Scenarios

- Centrifugal and process pumps are exposed to abrasive solids or high particulate content, where seal face protection is critical.

- Applications requiring positive isolation between process fluid and atmosphere to reduce leakage, emissions, and contamination.

- Pumps operating under variable pressure, temperature, and flow conditions, where stable sealing and controlled lubrication are essential.

- Systems that require barrier-fluid support plans to manage heat, prevent dry running, and extend seal life in harsh environments.

Why It Fits These Applications

- The double-cartridge design ensures consistent face loading and minimizes installation error while protecting both inboard and outboard seal faces.

- Active barrier-fluid circulation provides continuous lubrication and heat dissipation, critical for abrasive and slurry services.

- The seal’s construction helps prevent the ingress of solids into the sealing interface, reducing wear and extending service life.

- Cartridge assembly simplifies installation, alignment, and replacement, reducing downtime in maintenance-intensive operations.

Installation Guidelines

Prepare all mating surfaces

Ensure the shaft, seal chamber bore, and gland face are clean, smooth, and free from corrosion or scoring. Proper alignment and surface finish are essential for long-term seal performance.

Install the cartridge assembly

Position the SPS-625 cartridge evenly onto the shaft and into the seal chamber without forcing. Verify correct axial positioning before securing the gland.

Connect the barrier-fluid system

Ensure the barrier-fluid supply and return lines are correctly connected and that the system is fully vented to remove trapped air.

Commissioning startup

Establish stable barrier-fluid pressure and circulation before starting the pump. Monitor seal temperature, vibration, and leakage during initial operation.

Maintenance & Inspection Best Practices

- Monitor the barrier-fluid condition: regularly check the barrier-fluid pressure, cleanliness, and temperature. Degraded or contaminated barrier fluid reduces seal life.

- Inspect during planned shutdowns: Examine seal faces, secondary sealing elements, and cartridge components for wear, abrasion, or solid buildup.

- Track operating conditions: Maintain records of run hours, pressure changes, temperature fluctuations, and solids concentration to support predictive maintenance.

- Proactively replace wear components: secondary seals, barrier-fluid filters, and worn components should be replaced on a scheduled basis rather than after failure.

- Evaluate changes in service: If solids content, pressure, or operating temperature increases, reassess seal configuration and materials to maintain reliability.

Service & Support Options

- Application review and seal selection support to ensure face materials and elastomers are correctly matched to slurry characteristics and operating conditions.

- Barrier-fluid system guidance to optimize circulation, cooling, and pressure control for extended seal life.

- Spare parts and rebuild support to minimize downtime during maintenance or overhauls.

- Preventive maintenance planning based on actual operating data and service severity.

- Upgrade consultation for more aggressive services that require enhanced materials or alternative seal configurations.

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049