Compact Double Seal CSW-610 – Durable Industrial Seal Solution

Compact Double Seal CSW-610 – Durable Industrial Seal Solution

Overview

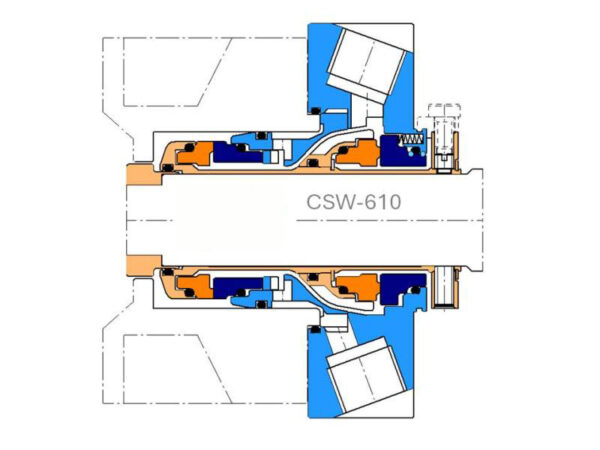

HydroMax Seal CSW-610 | Compact Double Cartridge Seal with Bi-Directional Barrier Fluid Pumping

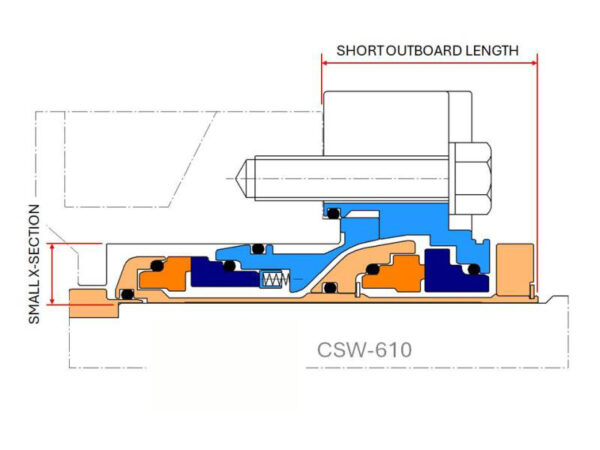

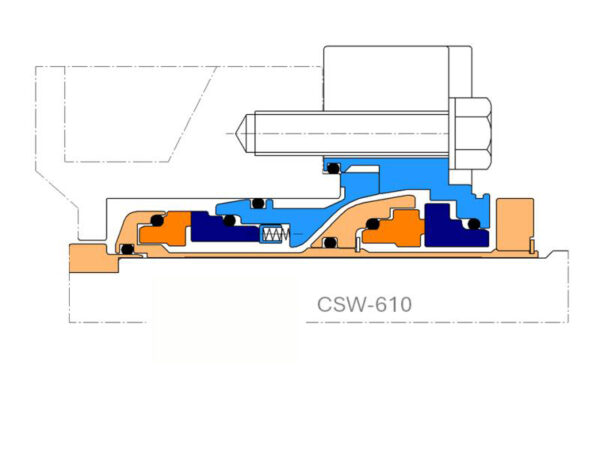

The CSW-610 is a compact, double-cartridge mechanical seal specifically engineered for equipment with short outboard lengths and small cross-section seal chambers, as typically found in compact process pumps used in the Pulp & Paper and Water & Waste industries.

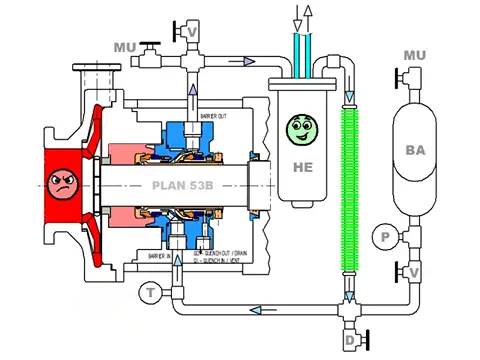

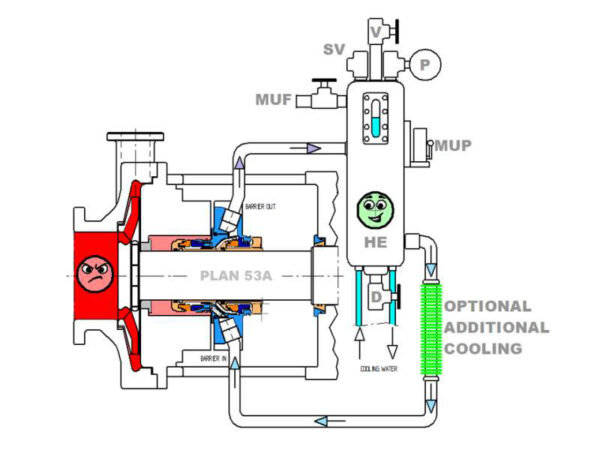

This stationary seal design features an integrated bi-directional pumping ring, optimized for Plan 53, 53A, 53B, and 53C piping systems, ensuring high thermal performance and pressure stability.

Product Description

Design Features

- Compact double cartridge seal for tight equipment clearances

- 3/8″ NPT barrier fluid ports (BI/BO) for Plan 53 or 52 configurations

- The integral flow deflector directs barrier fluid to both inboard and outboard faces for efficient cooling

- API682-compliant clearances for high-integrity sealing

- Monolithic seal faces offer improved thermal resistance

- Self-aligning stationary seal face is ideal for high-speed operation

- Multi-spring design, with springs located outside the process fluid

- Equipped with a high-efficiency bi-directional pumping ring

- Designed for use with Plan 53A, 53B, and 53C Seal Support Systems

Technical Specifications

| Seal Shaft Sizes | All sizes |

| System Vessel Sizes | 3.17 US gallons and 7.40 US gallons |

| Inboard Seal Face Combinations | TC/TC, Car/TC, Ant.Car/RB SiC, Ant.Car/TC, RB SiC/RB SiC |

| Outboard Seal Face Combinations | Car/TC, Car/RB SiC, Ant.Car/RB SiC, Ant.Car/TC, TC/TC |

| Gasket Materials | PTFE, AF1 |

| Secondary Sealing Materials | Viton, Alfas, ERP, Kalrez |

| Shaft Speeds | Up to 4,000 rpm |

| Pressures | Up to 362.6 psig |

| Instrumentation | Designed for use with a Plan 53 piping system |

| Temperatures | Up to 482°F |

The CSW-610 delivers high reliability and performance in space-constrained installations where standard seal designs are not feasible.

Typical Applications & Industry Use Cases

The CSW-610 Compact Double Cartridge Seal is a space-saving double-cartridge mechanical seal designed for pumps with limited seal-chamber depth and restricted gland dimensions. It incorporates an internal bi-directional barrier-fluid pumping ring, enabling effective circulation, cooling, and lubrication of both inboard and outboard seal faces. This design supports dual-seal piping arrangements such as Plan 53-style systems and delivers reliable containment for demanding fluid services.

Industries Served

Pulp and paper processing

compact process pumps requiring dual sealing in confined seal chambers

Water and wastewater treatment

booster pumps and packaged systems with limited installation space

Chemical and petrochemical processing

clean to lightly contaminated chemical services requiring dual containment

OEM compact pump systems

engineered skids and packaged units where space efficiency is critical

Industrial utilities

circulation and transfer pumps needing enhanced leakage control

Equipment & Use-Case Scenarios

- Compact centrifugal and process pumps with short stuffing-box depths or reduced axial seal space.

- Dual-seal applications requiring a pressurized barrier fluid for face lubrication and heat removal

- High-speed rotating equipment where thermal stability and face alignment are critical

- Installations where upgrading from a single seal to a dual seal is required without major pump modification

- Applications needing enhanced containment to protect equipment, personnel, or the environment

Prepare mating surfaces

Thoroughly inspect and clean the pump shaft, seal chamber bore (or gland face), and shaft sleeve. Remove corrosion, scoring, or debris before installation.

Why It Fits These Applications

- The integral bidirectional pumping ring ensures continuous circulation of barrier fluid, improving cooling and extending seal-face life.

- Stationary seal face design helps accommodate shaft movement and reduces sensitivity to vibration and misalignment.

- Compact cartridge construction allows installation in pumps that cannot accommodate conventional double seals.

- A multi-spring configuration with springs isolated from the process fluid improves reliability and reduces the risk of clogging.

- Dual-seal arrangement improves containment, reduces leakage risk, and enhances operational safety.

Installation Guidelines

Surface preparation

Ensure the pump shaft, seal chamber bore, and gland face are clean, smooth, and free of corrosion or debris. Proper alignment and surface finish are critical for optimal performance.

Seal installation

Insert the CSW-610 cartridge carefully into the seal chamber without forcing. Confirm correct axial positioning and proper engagement of the cartridge hardware.

Barrier-fluid connections

Connect the inlet and outlet ports to the selected barrier-fluid system. Ensure the loop is properly vented and filled before startup.

Commissioning

Establish barrier-fluid circulation and pressure prior to pump startup. Bring the pump online gradually while monitoring seal temperature, pressure, and leakage.

Baseline recording

Document initial operating parameters such as barrier-fluid pressure, temperature, and flow for future reference.

Maintenance & Inspection Best Practices

- Barrier-fluid monitoring: Regularly check barrier-fluid pressure, cleanliness, and circulation. Degraded fluid quality can shorten seal life.

- Routine inspections: During scheduled shutdowns, inspect cartridge components, seal faces, secondary seals, and springs for wear or damage.

- Operational logging: Maintain records of operating conditions, including speed, pressure, temperature, and fluid characteristics, to support predictive maintenance.

- Secondary seal replacement: Replace O-rings and gaskets during planned maintenance to prevent unexpected leakage.

- Condition review: If operating conditions change — higher speed, temperature, or solids content — reassess seal suitability and material selection.

Service & Support Options

- Application review: Assistance with seal selection, material compatibility, and barrier-fluid system configuration

- Commissioning support: Guidance during installation and startup to ensure correct setup and reliable operation

- Spare-parts availability: Replacement seal faces, elastomers, springs, and cartridge hardware to minimize downtime

- Preventive maintenance planning: Condition-based inspection schedules to extend seal life and reduce unplanned failures

- Upgrade guidance: Support for material or design upgrades if service conditions become more demanding

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049