Role Of Bearings in Industrial Machinery

Bearings are a core part of almost every industrial machine. Pumps, motors, conveyors, and mixers all rely on bearings to support movement, handle loads, and keep equipment running smoothly. When bearings work properly, machines operate efficiently. When bearings fail, downtime, repair costs, and production losses increase quickly.

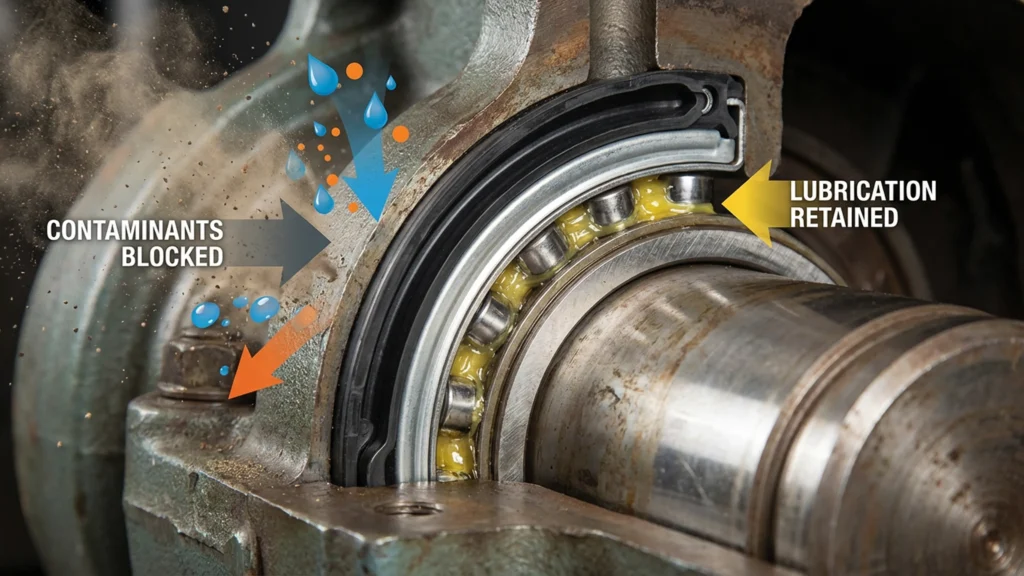

This is where bearing seals play a critical role. Although small in size, these components protect the internal bearing surfaces from harmful exposure. By controlling what enters the bearing and what stays inside, seals directly affect reliability, service life, and overall equipment performance.

Industrial machinery is constantly exposed to dust, moisture, chemicals, washdown fluids, and abrasive debris. Over time, these contaminants damage lubrication, increase friction, and wear down metal surfaces. Without proper machinery contamination protection, even high-quality bearings can fail much earlier than expected.

In this guide, we explain how sealing solutions protect internal components, reduce wear, and extend equipment life. You will learn how seals support wear-resistant bearings, how different seal designs function, and how correct selection and maintenance improve long-term reliability. Drawing on practical industry experience and design principles underpinning HydroMax Seal’s product approach, this article offers a clear, real-world view for engineers, maintenance teams, and decision-makers.

What Are Bearing Seals?

At a basic level, bearing seals are protective components installed between a bearing and the surrounding environment. Their main purpose is to control what enters and exits the bearing while still allowing the shaft to rotate smoothly.

In industrial use, seals must perform reliably across different speeds, temperatures, and exposure conditions. At HydroMax Seal, seal design focuses on consistent performance, durability, and efficiency in real operating environments. This includes both contact-style seals and advanced labyrinth designs used across a wide range of industrial applications.

The function of bearing seals can be understood through three key roles. First, they prevent contaminants such as dust, moisture, and process debris from entering the bearing. Second, they retain lubricant in the bearing cavity to control friction. Third, they help maintain bearing stability, thereby extending the service life of wear-resistant bearings in demanding equipment.

When rightly selected and installed, bearing seals operate quietly in the background. They stop contamination before damage begins and often determine whether a bearing reaches its expected lifespan or fails early.

Why Machinery Contamination Protection Matters

Most industrial machines do not operate in clean environments. Dust from raw materials, moisture from washdowns, airborne chemicals, and abrasive particles are common in daily operations.

Effective machinery contamination protection is important because contaminants damage bearings in several ways. Abrasive particles scratch metal surfaces, increasing wear. Moisture causes corrosion and breaks down lubricants. Chemicals can weaken seal materials and reduce their ability to protect internal components.

When contaminants pass through sealing systems, bearing surfaces wear faster. Friction rises, heat builds up, and lubrication loses its effectiveness. Over time, even high-quality, wear-resistant bearings lose performance when exposed to continuous contamination.

This is why bearing seals are essential system components, not optional add-ons. Proper machinery contamination protection slows wear, controls operating temperatures, and reduces the risk of sudden equipment failures that can interrupt production.

How Bearing Seals Work

Primary Mechanisms

The primary function of bearing seals is to serve as a physical barrier. They close off openings that would otherwise allow dust, moisture, and debris to reach sensitive bearing surfaces. This protection is especially important in environments with airborne particles or regular fluid exposure.

Another key function is lubrication retention. Seals keep grease or oil where it is needed inside the bearing. Proper lubrication reduces friction, limits metal-to-metal contact, and supports the long-term performance of wear-resistant bearings in continuous-use equipment.

Seal Contact Designs

Seal performance also depends on whether the seal touches the rotating shaft. Contact seals maintain a tight interface and are commonly used in dirty or harsh environments where maximum protection is required.

Non-contact and labyrinth seals use a different method. Designs such as HydroMax Seal’s LAB-series use internal pathways that make it difficult for contaminants to enter without direct contact. These designs reduce friction and heat while still providing reliable protection against machinery contamination in many applications.

Balance of Protection and Efficiency

Every sealing solution involves a trade-off. Tighter seals provide stronger protection but can increase friction. Looser designs reduce drag but may allow more exposure. Selecting the right seal design helps protect wear-resistant bearings, maintain efficiency, and control energy use.

Types of Bearing Seals and Their Industrial Applications

Choosing the right bearing seals is one of the most important factors in bearing performance. Different operating environments place different demands on sealing systems, and no single design works for every application. Understanding how each seal type functions helps ensure proper machinery contamination protection and longer bearing life.

- Contact Seals: Lip and Elastomeric Designs

Contact seals are one of the most commonly used bearing seals in industrial equipment. These seals stay in direct contact with the rotating shaft or inner ring, creating a tight barrier that prevents contaminants from entering the bearing.

These seals are typically made of rubber or polymer and are well-suited for environments with constant exposure to dust, dirt, and moisture. Motors, gearboxes, pumps, and material-handling equipment often use contact seals to protect wear-resistant bearings from premature wear.

The main advantage of contact seals is strong contamination control. Because they touch the rotating surface, they block contaminants effectively. However, this contact creates friction. Over time, friction generates heat and causes gradual seal wear. This makes proper material selection and surface finish important for long service life.

When properly selected and maintained, contact seals provide reliable protection against machinery contamination and are ideal for low- to moderate-speed equipment operating in harsh conditions.

- Non-Contact and Labyrinth Seals

Non-contact bearing seals take a different approach to contamination control. Instead of direct contact, these seals rely on precisely engineered pathways that prevent contaminants from reaching the bearing interior.

Labyrinth seals are a prime example. Their internal geometry forces dust, moisture, and debris to follow a long, indirect path, significantly reducing the chance of ingress. Because there is no physical contact with the rotating shaft, friction is minimized, and heat generation is reduced.

This design makes labyrinth seals particularly effective in high-speed or precision equipment where efficiency matters. Fans, compressors, electric motors, and rotating assemblies that operate continuously often benefit from non-contact sealing solutions.

HydroMax Seal’s labyrinth-style designs are engineered to balance low friction with strong protection against machinery contamination. When paired with wear-resistant bearings, these seals help maintain stable operating conditions without sacrificing efficiency.

- Specialty Seals for Demanding Environments

Some applications require more advanced bearing seals due to extreme operating conditions. Frequent washdowns, abrasive slurries, saltwater exposure, or strict hygiene standards place higher demands on sealing systems.

Industries such as food processing, marine operations, chemical plants, and wastewater treatment often require seals that withstand constant moisture and aggressive cleaning. In these environments, advanced materials and reinforced designs are essential.

HydroMax Seal offers sealing solutions designed for severe conditions, including seals that meet high ingress protection requirements. These seals maintain reliable protection against machinery contamination and help keep wear-resistant bearings protected even in the most challenging environments.

Wear-Resistant Bearings and the Role of Effective Sealing

Wear-resistant bearings are designed to handle heavy loads, repeated operation, and tough working conditions. However, even strong bearing materials cannot perform properly without effective sealing.

High-quality bearing seals directly affect the service life of wear-resistant bearings. When seals block contaminants and keep lubrication inside the bearing, metal surfaces experience less abrasion and lower friction. This slows wear and helps maintain stable operating temperatures.

Lubrication is a key part of this process. Seals that retain grease or oil maintain a consistent lubricating film between rolling elements and raceways. This reduces metal-to-metal contact and spreads loads evenly, which is essential for extending bearing life.

In critical equipment such as pumps, conveyors, mixers, and industrial drives, seal failure often causes bearing failure. By using reliable bearing seals, operators protect wear-resistant bearings, reduce unexpected downtime, and improve overall equipment reliability.

Choosing the Right Bearing Seal for Your Equipment

Seal selection should never be an afterthought. Choosing the wrong seal can undermine even the best bearing design, while the right seal enhances reliability across the entire system.

Application-Specific Considerations

Every application has different environmental and operating challenges. Temperature extremes can affect seal flexibility. High dust or debris levels increase the risk of contamination. Moisture exposure increases the risk of corrosion and lubricant degradation.

Operating speed and load also influence seal selection. High-speed equipment often requires low-friction designs, while slower, heavily loaded machinery may need tighter sealing for better machinery contamination protection. Maintenance access is another important factor. Equipment that is difficult to service benefits from seals designed for long life and consistent protection.

Understanding these conditions helps engineers and maintenance teams select bearing seals that perform in real-world environments, not just on paper.

Material and Design Considerations

Seal materials play a major role in performance and lifespan. Elastomers offer flexibility, while engineered materials provide greater resistance to heat, chemicals, and wear.

Design accuracy is equally important. Seals that are too tight increase friction and wear. Seals that are too loose allow contaminants to enter. Precision design and manufacturing help ensure consistent performance across different temperatures and operating cycles.

HydroMax Seal focuses on practical seal designs that deliver durability and reliability. The goal is to provide seals that work effectively with wear-resistant bearings and maintain long-term protection against machinery contamination in real industrial conditions.

Best Practices for Seal Maintenance and Long-Term Performance

Even well-designed bearing seals need proper maintenance to perform reliably over time. Regular inspection helps detect early signs of wear, hardening, or leakage before damage reaches the bearing.

Lubrication practices should match the sealed bearing design. Too much lubrication can create internal pressure and push seals out of position. Too little lubrication increases friction and heat. Using compatible lubricants also helps preserve seal materials and maintain effective protection against contamination.

Deciding whether to repair or replace seals depends on operating conditions. In cleaner environments, refurbishment may restore seal performance. In harsh or highly contaminated environments, replacement is often the safer option for long-term reliability.

Consistent maintenance extends seal life and helps ensure wear-resistant bearings continue to operate as intended.

Case Studies and Real-World Performance Outcomes

Many bearing failures in industrial equipment can be traced back to poor sealing. A common example is moisture entering the bearing during washdowns. When this happens, lubrication breaks down, corrosion starts, and friction increases. The bearing fails well before its expected service life.

In contrast, facilities that upgrade to properly selected bearing seals often see clear improvements. Better sealing reduces contamination, keeps lubrication stable, and lowers operating temperatures. As a result, wear-resistant bearings last longer and require less frequent replacement.

These improvements lead to higher equipment uptime and more predictable maintenance schedules. Reduced unexpected failures also lowers repair costs and minimizes production disruptions.

Across industries, the pattern is consistent. Strong machinery contamination protection leads to better reliability, lower maintenance effort, and improved overall equipment performance.

HydroMax Seal’s Role in Protecting Industrial Equipment from Wear and Contamination

HydroMax Seal designs bearing seals with one objective: keeping industrial equipment running under real operating conditions. In environments where dust, moisture, and abrasive debris are constant threats, sealing performance directly determines bearing life and equipment reliability.

By controlling contaminant entry and maintaining lubrication stability, HydroMax Seal bearing seals reduce friction, limit surface damage, and protect wear-resistant bearings from premature failure. Each seal is developed with practical factors in mind, including operating speed, exposure levels, and maintenance realities, not ideal lab conditions.This application-driven approach enables HydroMax Seal to deliver consistent protection against machinery contamination across a wide range of industrial systems. The result is longer service life, fewer unplanned shutdowns, and more predictable maintenance cycles. In reliability-focused operations, effective sealing is not optional. It is foundational, and HydroMax Seal plays a major role in making that protection work where it matters most.