Double Cartridge Seal SPS-610 – Durable Industrial Mechanical Seal

Double Cartridge Seal SPS-610 – Durable Industrial Mechanical Seal

Overview

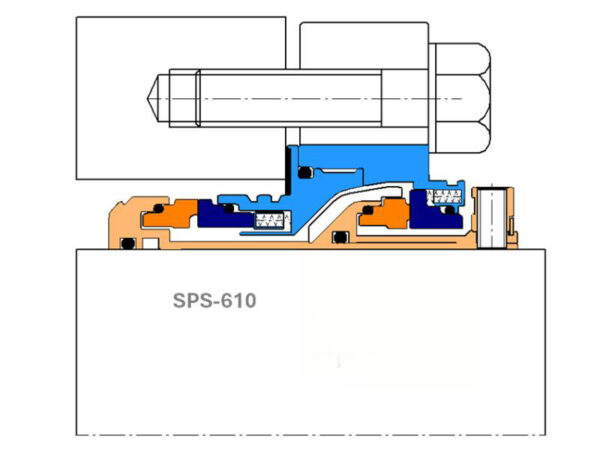

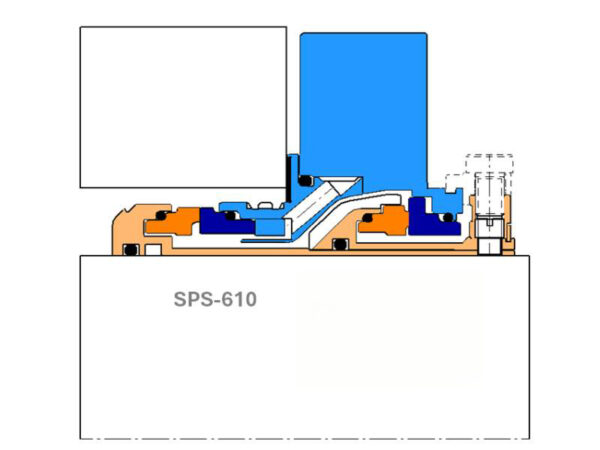

HydroMax Seal SPS-610 | Double Cartridge Seal for Slurry Applications with Bi-Directional Barrier Fluid Ring

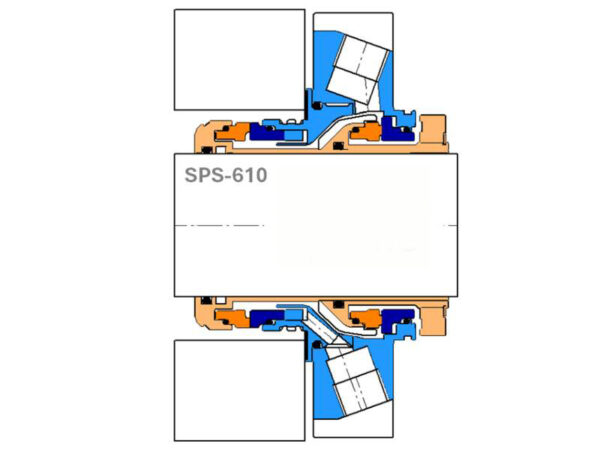

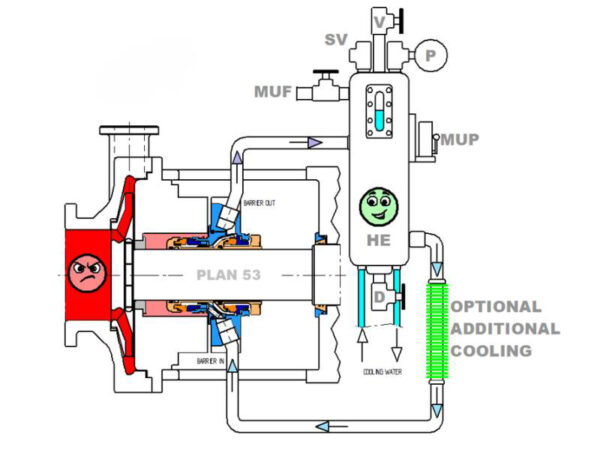

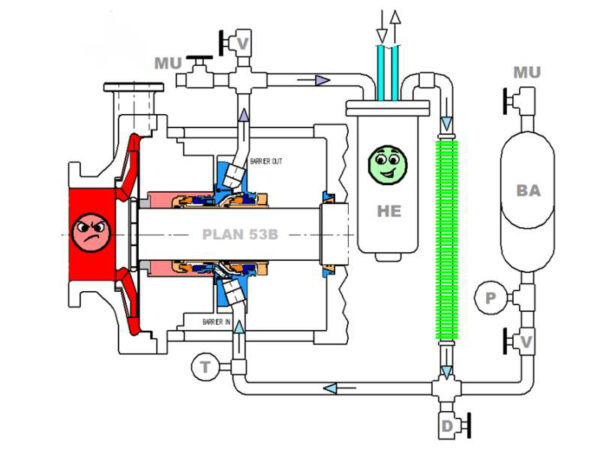

The SPS-610 is a double-cartridge mechanical seal designed for slurry applications in sectors such as mining and minerals, pulp and paper, and water and waste. It features an integrated bi-directional barrier fluid pumping ring, optimized for use with Plan 53, 53A, 53B, and 53C piping systems.

This stationary seal design incorporates advanced features, such as vortex breakers and monolithic seal faces, making it ideal for systems that handle solids or suspended particles.

Product Description

Design Features

- 1/2″ NPT barrier fluid ports (BI/BO) for compatibility with Plan 53 or 52

- The integral flow deflector ensures effective cooling across both seal faces

- Gland insert with vortex breakers enhances performance in slurry/media with particulates

- API682-compliant radial clearances for optimized sealing

- Monolithic seal faces support high-temperature durability

- Self-aligning stationary design for high-speed operation

- Multi-spring configuration, springs isolated from process fluid

- Bi-directional pumping ring maximizes heat removal efficiency

- Works with Plan 53A, 53B, or 53C Seal Support Systems

Technical Specifications

| Seal Shaft Sizes | All sizes supported |

| System Vessel Sizes | 3.17 US gallons 7.40 US gallons |

| Inboard Seal Face Combinations | TC/TC Car/TC Ant.Car/RB SiC Ant.Car/TC RB SiC/RB SiC |

| Outboard Seal Face Combinations | Car/TC Car/RB SiC Ant.Car/RB SiC Ant.Car/TC TC/TC |

| Gasket Materials | Spiral Wound Stainless Steel Graphite |

| Secondary Sealing Materials | Viton Alfas ERP Kalrez |

| Shaft Speeds | Up to 4,000 rpm |

| Pressures | Up to 362.6 psig |

| Instrumentation | Designed for integration with Plan 53 systems |

| Temperatures | Up to 482°F |

The HydroMax SPS-610 is a rugged and high-performance sealing solution for abrasive and particle-laden fluid applications, delivering reliability in thin cross-section seal chambers.

Typical Applications & Industry Use Cases

The SPS-610 Double Cartridge Seal is a heavy-duty, double-cartridge mechanical seal designed for abrasive, solids-bearing, and slurry-type services. It features a bi-directional barrier-fluid pumping ring, large barrier-fluid ports, and a vortex-breaker gland insert to promote effective circulation of barrier fluid, heat removal, and reduction of abrasive effects at the sealing interface. This robust design delivers extended service life in challenging environments where standard seals wear prematurely.

Industries Served

Mining and mineral processing

tailings transfer, slurry feed, flotation, thickener underflow

Pulp & paper

pulp stock, paper machine effluent, and fiber-laden fluid handling

Water and wastewater treatment

- sludge, grit, and solids-bearing effluent pumping

Heavy industrial and process plants

abrasive fluid handling, solids-laden systems

Equipment & Use-Case Scenarios

- Centrifugal and process pumps handling abrasive slurries or fluids with high solids content

- Pumps with limited seal chamber space that still require a robust double-seal arrangement

- Systems with external barrier-fluid plans where effective circulation and heat dissipation improve sealing performance

- Installations with fluctuating pressure and temperature where a stable dual-seal design enhances reliability

Why It Fits These Applications

- The bi-directional barrier-fluid pumping ring promotes continuous circulation of clean barrier fluid across both inboard and outboard faces, improving cooling and sealing reliability.

- Large barrier-fluid ports enable high flow in Plan-type barrier systems, thereby increasing fluid-film lubrication and heat removal.

- The vortex-breaker gland design reduces turbulence and minimizes the risk of abrasive particles swirling near the seal faces.

- Cartridge-style double-seal construction simplifies installation and service, reducing maintenance time and error compared with component seals.

Installation Guidelines

Surface preparation

Before installation, thoroughly clean and inspect the pump shaft, seal chamber bore, and gland face. Remove corrosion, scoring, nicks, or debris to ensure accurate alignment and optimal sealing.

Cartridge insertion

Carefully insert the SPS-610 cartridge into the gland or seal chamber. Do not force the unit; ensure the barrier-fluid pumping ring is seated correctly and the faces are aligned.

Barrier-fluid connections

Connect the barrier-fluid supply and return lines according to your barrier-fluid plan. Prime and vent the loop to eliminate air pockets before startup.

Commissioning checks

Begin with barrier-fluid circulation, verify flow and pressure stability, then start the pump under controlled conditions while observing sealing performance and temperature.

Maintenance & Inspection Best Practices

- Support-fluid monitoring: Routinely check barrier-fluid loop performance — flow rate, pressure drop, and temperature. Early changes can signal clogging, wear, or fluid contamination.

- Scheduled inspections: During planned shutdowns, inspect the seal faces, pumping ring, springs, secondary seals, and gland surfaces for signs of abrasion, wear, or deposits.

- Operational logging: Maintain a log of fluid properties, shaft speed, pressure, temperature, and any anomalies. Trend analysis helps with predictive maintenance and scheduling.

- Replace consumables proactively: Change barrier-fluid filters, O-rings, and gaskets at scheduled intervals rather than waiting for visible failure; cleaning the barrier fluid extends seal life.

- Re-evaluate with service changes: If operating conditions change — such as higher solids, higher speed, or more abrasive media — reassess material and design to ensure continued reliability.

Service & Support Options

- Specification review: Confirm that material choices for seal faces and elastomers are suitable for the fluid chemistry, temperature, and pressure.

- Spare parts availability: Keep replacement seal faces, secondary seals, and pumping-ring components in inventory to reduce maintenance downtime.

- Installation and commissioning support: Assistance with alignment and barrier-fluid setup can help ensure correct first-run performance.

- Preventive-maintenance planning: Scheduled inspections and lifecycle tracking help maximise mean time between maintenance cycles.

- Upgrade guidance: If service demands intensify (higher pressure, abrasive fluids, increased temperature), explore alternative materials or enhanced seal configurations.

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049