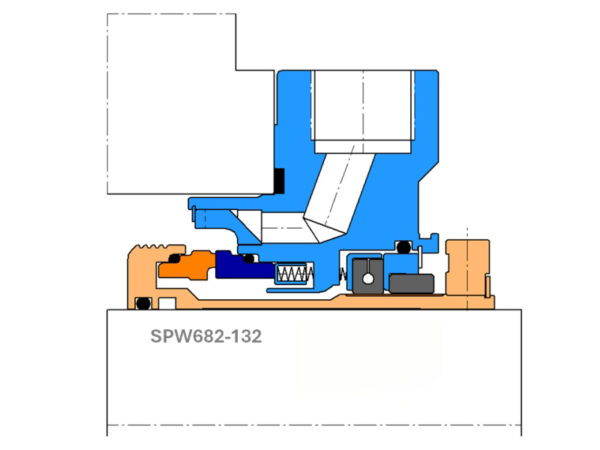

Durable Single Cartridge Mechanical Seal SPW682-132

Durable Single Cartridge Mechanical Seal SPW682-132

Overview

HydroMax Seal SPW682-132 | API682-Compliant Single Cartridge Seal for Plan 32 Systems

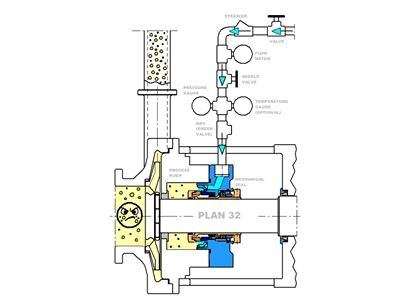

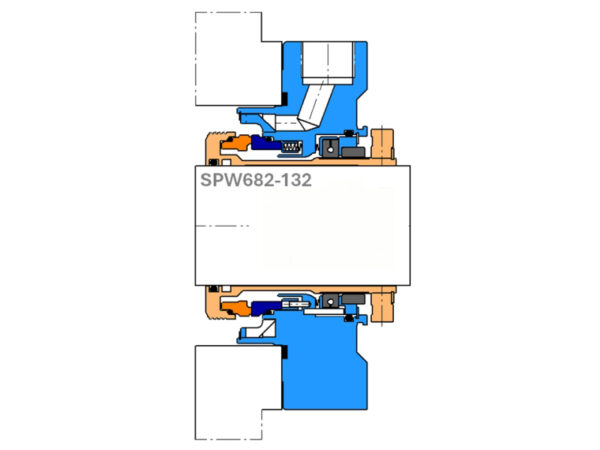

The SPW682-132 is a high-performance single-cartridge mechanical seal designed with a multi-port flush ring in the gland plate and a unique combination of segmented and floating outboard restriction bushes. Engineered to meet API682 specifications, this seal is optimized for critical Oil & Gas applications and is compatible with API Plan 32 arrangements on API610 V8+ process pumps.

The stationary cartridge configuration is fully assembled and tested, making it an ideal solution for high-speed and particle-laden process fluid environments.

Product Description

Design Features

- Multi-port flush orifice in the gland plate delivers a uniform shower of clean, cooling, and lubricating fluid to inboard seal faces—ideal for suspended particle applications

- Quench and Drain ports support Plan 62 or 52 configurations; integral deflector ensures directed delivery of buffer or steam fluid

- Large 1/2″ NPT seal port orifices for improved system compatibility

- Gland plate includes a multi-port flush ring for enhanced fluid distribution

- API682-compliant radial clearances between rotary and stationary components

- Monolithic seal faces offer superior high-temperature durability

- Stationary seal design with self-aligning stationary face ensures stability in high-speed applications

- Multi-spring configuration with springs isolated from the process fluid

- Segmented + floating outboard restriction bush combo delivers exceptional performance and reliability

- Compatible with Plan 32 kits, including pressure gauge, valves, flow meter, and strainer

Technical Specifications

| Seal Shaft Sizes | All |

| System Vessel Size | 3.17 US gallons and 7.40 US gallons |

| Inboard Seal Face Combinations | TC/TC Car/TC Ant.Car/RB SiC |

| Gasket | Spiral Wound Stainless Steel, Graphite |

| Secondary Sealing | Viton Alfas ERP Kalrez |

| Shaft Speeds | Up to 4,000 rpm |

| Pressures | Up to 580.2 psig |

| Instrumentation | Used with Plan 32 piping systems |

| Temperatures | Up to 302°F |

The SPW682-132 is a robust and innovative stationary seal solution, purpose-built for API682 compliance in demanding process environments

Typical Applications & Industry Use Cases

The SPW682-132 Single Cartridge Mechanical Seal is a high-performance, API 682–compliant single-cartridge seal engineered for use with API Plan 32 piping arrangements on API 610 V8 and newer process pumps. It is designed to deliver reliable sealing performance in demanding process environments, particularly where suspended solids are present, and continuous flush circulation is required for cooling and lubrication.

Industries Served

Oil and gas and hydrocarbon processing

Chemical processing facilities

Refining and petrochemical transfer systems

Water treatment and utility operations handling particulate fluids

General industrial pumping systems requiring API-level sealing reliability

Equipment & Use-Case Scenarios

- Single-seal configurations on API 610 process pumps where API 682 compliance is required

- Applications using Plan 32 flush systems for improved seal-face cooling and lubrication

- Services handling suspended solids or contaminants that benefit from distributed flush delivery

- Installations where fully assembled cartridge seals reduce installation time and minimize assembly errors

Why It Fits These Applications

- Multi-port flush orifice delivers an even spray of clean fluid across the inboard seal faces, improving cooling and reducing solids-related wear

- Integrated quench and drain ports compatible with Plan 62 and Plan 52 arrangements, with a deflector that directs steam or buffer fluid effectively

- API 682–compliant internal clearances enhance alignment, stability, and long-term performance

- Monolithic seal face construction improves thermal resistance and durability in elevated-temperature services

- Segmented and floating restriction bush design enhances sealing reliability in demanding process conditions

Installation Guidelines

Pre-Installation Preparation

Thoroughly clean and inspect the pump shaft, seal chamber bore, and gland face. Remove corrosion, debris, or surface damage to ensure proper alignment and sealing integrity.

Cartridge Installation

Carefully install the SPW682-132 cartridge into the seal chamber, ensuring the multi-port flush ring and all ports are correctly oriented to match the selected Plan 32 piping arrangement. Secure all fasteners according to specification.

Support-Fluid Connections

Connect flush, quench, and drain lines in accordance with the applicable API piping plan. Prime and vent all lines to remove trapped air and confirm consistent fluid flow before startup.

Controlled Startup

Start support-fluid circulation first, then gradually bring the pump to operating speed. Monitor flush flow, seal-face temperature, vibration, and leakage during initial operation.

Maintenance & Inspection Best Practices

- Monitor flush and quench system performance, including flow rates, pressure, and fluid cleanliness

- Perform scheduled inspections during shutdowns to check seal faces, springs, restriction bushings, and secondary seals for wear or corrosion

- Maintain operating logs tracking pressure, temperature, speed, and fluid properties to support predictive maintenance

- Replace secondary seals and filters on a preventive schedule to maximize service life

- Reassess seal materials and support-fluid plans if process conditions change, such as increased temperature, pressure, or solids content

Service & Support Options

- Application reviews to confirm material compatibility and piping plan suitability

- Spare parts planning to ensure replacement faces, elastomers, springs, and hardware are readily available

- Installation and commissioning support to ensure correct orientation and first-run performance

- Preventive maintenance programs based on operating history and duty conditions

- Evaluation of upgraded materials or configurations for more severe or evolving service requirements

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049