HydroMax Seal SPW131 – Durable Mechanical Seal for Pumps

HydroMax Seal SPW131 – Durable Mechanical Seal for Pumps

Overview

Compact Single Cartridge Mechanical Seal for API Plan 31 Systems

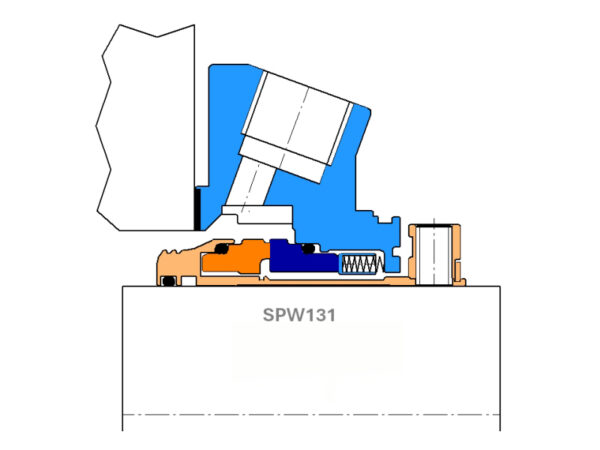

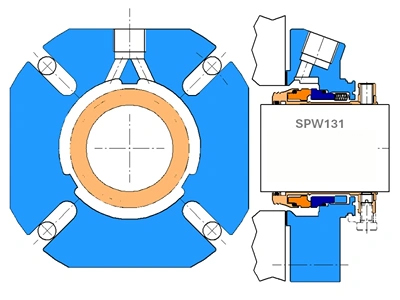

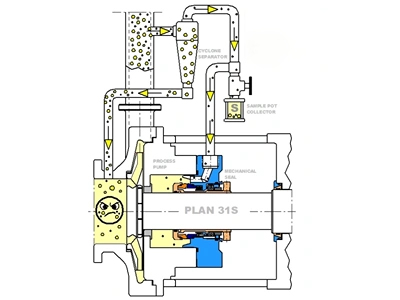

The SPW131 from HydroMax Seal is a single-cartridge mechanical seal engineered for space-constrained applications and compliant with API610 Edition 5 onwards. Specifically designed for API Plan 31 piping arrangements, it offers robust sealing performance when handling process fluids containing suspended particles or solids.

This cartridge seal integrates vortex breakers within the gland plate, reducing turbulence and protecting the stationary face in slurry-rich or particle-laden systems.

Product Description

Design Features

- Flush orifice optimized for Plan 31 systems — engineered to avoid abrasive impact on the stationary seal face when handling particulate-containing flush liquids

- Large ½″ NPT seal port orifices for improved flushing and system compatibility

- Gland plate with integrated vortex breakers to manage flow and reduce erosion risks

- Compact stationary cartridge design with reduced inboard and outboard lengths

- Ideal for small cross-sectional seal chambers in retrofits and compact equipment

- Multi-spring design with springs fully isolated from the process media for extended lifespan

- Hydraulic and pressure-balanced seal face geometry for consistent performance

- Monolithic seal faces provide thermal stability and high-temperature durability

- Designed to be used alongside HydroMax Seal’s Plan 31 Cyclone Separator System and Sample Collection Pot for advanced particulate management

Technical Specifications

| Seal Shaft Sizes | All standard and custom sizes supported |

| Inboard Seal Face Combinations | TC / TC Carbon / TC Antimony Carbon / RB SiC |

| Gasket Material | Spiral Wound Stainless Steel with Graphite |

| Secondary Sealing Materials | Viton, Alfas, ERP, Kalrez |

| Maximum Shaft Speed | Up to 4,000 RPM |

| Maximum Pressure Rating | Up to 25 Barg |

| Instrumentation | Compatible with Plan 31 piping systems |

| Operating Temperature | Up to 302°F |

The SPW131 embodies HydroMax Seal’s commitment to delivering compact, API-compliant sealing solutions with best-practice engineering. Ideal for applications involving abrasive media, it ensures long-lasting performance with minimal maintenance.

Typical Applications & Industry Use Cases

The SPW131 is a single-cartridge mechanical seal engineered for tight-envelope pump installations. It features integral vortex-breaker grooves in the gland. It is optimised for API Plan 31 flush/cyclone separator systems—making it particularly well-suited for handling fluids with suspended particles or solids when space is constrained.

Industries Served

Chemical processing

small to medium centrifugal pumps handling solvent, slurry, or particulate-laden fluids under flush conditions.

Water treatment and utilities

booster pumps and service equipment, where space is limited and a compact cartridge solution is required.

Mining and minerals

compact pump skids for pulp-stock, tailings, or process-water applications where solids handling and a minimal envelope are key.

OEM pump assemblies

where retrofit or tight fit-up installs benefit from a short inboard/outboard seal cartridge and a reliable flush arrangement.

Equipment & Use-Case Scenarios

- Centrifugal pumps with minimal gland space and a restricted cross-section require a short-length cartridge seal.

- Applications requiring a flush or cyclone separator support (Plan 31) to remove solids or maintain seal chamber cleanliness.

- Retrofit of older pump frames, upgrading to a cartridge seal to improve reliability without major mechanical modifications.

- Systems with shaft sizes across the typical range, speeds up to approximately 4,000 rpm, and flush/cyclone support arrangements.

Why It Fits These Applications

- The integral vortex-breaker design in the gland plate reduces swirl and back-flush turbulence, improving performance in solids-bearing fluid services.

- Compact cartridge format enables fit-up in tight mechanical layouts, reducing installation time and maintenance effort.

- Hydraulically balanced monolithic seal faces promote thermal stability and reduce face loading in varied pressure and temperature environments.

- Multi-spring loading located outside the process fluid helps improve longevity by reducing exposure of spring elements to contamination.

Installation Guidelines

Confirm that the pump shaft, seal chamber bore, and gland face are clean, aligned, and within tolerance prior to installation. Remove any scoring, build-up, or debris.

Insert the cartridge carefully into the gland or onto the shaft without forcing the unit; ensure the vortex-breaker grooves align with the flush/cyclone ports, and that the set-screw drive is engaged correctly.

Connect the flush/cyclone separator piping as per your Plan 31 system; ensure the flush inlet/outlet are correctly oriented; vent the system, and begin circulation before full operation.

Before ramping to full load, verify that operating parameters (shaft speed, flush flow, solids content, temperature, pressure) are within specification for the SPW131. Record baseline data for face temperature, flush flow, and chamber conditions.

Ensure installation data and baseline performance readings are logged to support future maintenance planning and service intervals.

Maintenance & Inspection Best Practices

- Monitor flush or cyclone loop performance: check flow rate, differential pressure across strainer/mesh, flush fluid cleanliness, and temperature rise. Any deviation may indicate seal face wear or restriction.

- During scheduled shutdowns, remove the cartridge for inspection if feasible: check the seal face condition, springs, secondary seals (O-rings/gaskets), and for build-up or erosion.

- Maintain an operational log tracking key parameters, including fluid type and contamination level, shaft speed changes, flush system performance, start-stop cycles, vibration, and temperature excursions. Use this data to refine maintenance intervals and anticipate seal life.

- Replace secondary seals and refresh flush/cyclone loop components on a preventive schedule—not only when failures occur. Keeping the flush system clean and effective enhances seal longevity.

- If process conditions shift (e.g., higher solids content, increased speed, different fluid chemistry), reevaluate whether the SPW131 remains fit for purpose. Upgrades in material selection or flush/support plan may be needed.

Service & Support Options

- Pre-installation consultation: ensure correct seal face materials (e.g., Car/TC, Car/SiC, TC/TC), elastomer selection (Viton, Aflas, Kalrez), and flush/cyclone system compatibility are specified correctly.

- Field or remote commissioning: validate flush/cyclone flow and temperature, monitor seal-face temperatures under actual load, and ensure correct installation settings.

- Spare parts kits are available specifically for the SPW131, including seal faces, O-rings/gaskets, springs, set-screw drives, and cartridge hardware, to reduce maintenance downtime.

- Upgrade path services: should service conditions intensify (higher speed, increased solids, or more aggressive fluids), options exist to migrate to higher duty materials or an alternate cartridge design.

- Preventive maintenance programmes: scheduled inspections, performance trending, condition-based monitoring to reduce unplanned downtime, increase mean time between maintenance, and lower total lifecycle cost.

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049