HydroMax Seal SPW682-123 – Durable Mechanical Seal for Pumps

HydroMax Seal SPW682-123 – Durable Mechanical Seal for Pumps

Overview

High-Temperature Stationary Cartridge Mechanical Seal for API Plan 23 Systems

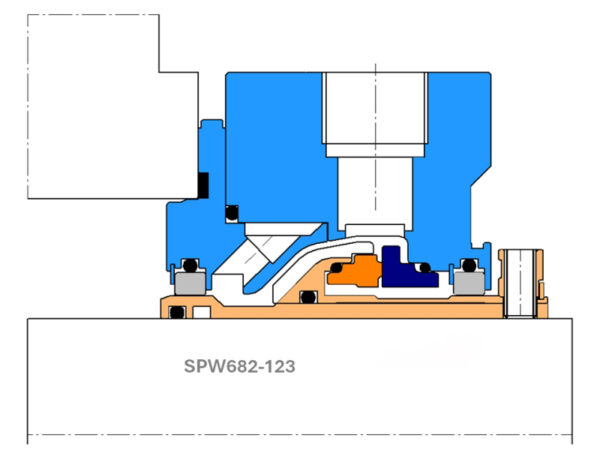

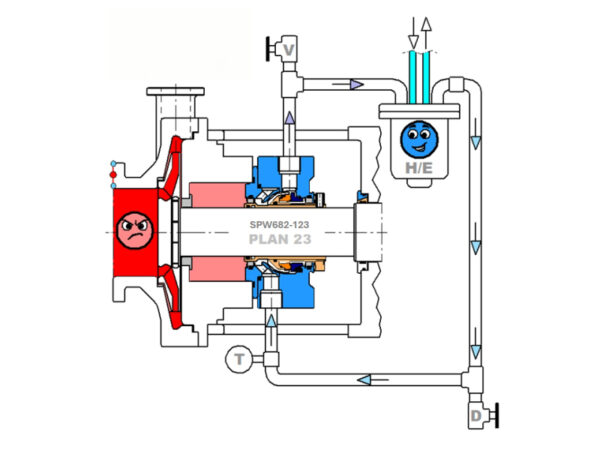

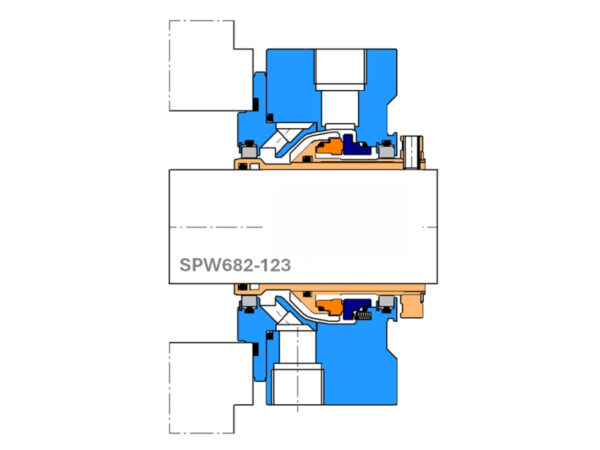

The SPW682-123 by HydroMax Seal is a specialized single-cartridge mechanical seal, designed in full compliance with API682 specifications for demanding Oil & Gas applications. It is engineered for API Plan 23 systems used on API610 V8 and later process pumps, delivering exceptional performance in high-speed and high-temperature sealing environments.

This complete cartridge seal incorporates dual floating restriction bushings—an inboard bush integrated into the gland plate and an outboard bush, enhancing pressure regulation and flow control across the seal chamber.

Product Description

Design Features

- Flush port configuration tailored for Plan 23 systems, promoting efficient thermal control through recirculated barrier fluid

- Quench and drain ports support Plan 62 arrangements, enhancing cooling and leak containment

- 1/2″ NPT seal port orifices for optimal flow capacity

- Integrated deflector in gland directs flush fluid precisely to the inboard sealing faces

- Radial clearances meet or exceed API 682 best practice standards for enhanced alignment and operation

- Monolithic seal faces ensure long-term durability in high-temperature applications

- Self-aligning stationary seal face design suited for high-speed rotary equipment

- Multi-spring design promotes uniform face loading and extends service life

- Designed for use with HydroMax Seal’s Plan 23 Heat Exchanger System, including temperature control accessories and instrumentation

Technical Specifications

| Seal Shaft Sizes | All standard and custom sizes supported |

| System Vessel Sizes | 3.17 gallons and 7.40 gallons |

| Inboard Seal Face Combinations | TC / TC Antimony Carbon / TC Antimony Carbon / RB SiC RB SiC / RB SiC |

| Gasket Material | Spiral Wound Stainless Steel with Graphite |

| Secondary Sealing Options | Viton, Alfas, ERP, Kalrez |

| Maximum Shaft Speed | Up to 4,000 RPM |

| Maximum Pressure | Up to 40 Barg |

| Instrumentation | Designed for seamless integration with Plan 23 systems |

| Operating Temperature | Up to 662°F |

The SPW682-123 exemplifies HydroMax Seal’s expertise in advanced mechanical sealing solutions, offering a high-integrity, API682-compliant design tailored for extreme thermal and pressure conditions.

Typical Applications & Industry Use Cases

The SPW682-123 is a high-performance double-cartridge mechanical seal designed for critical process applications in accordance with API 682 specifications. With its integrated barrier-fluid pumping ring, large port orifices, self-aligning stationary face, and vortex-breaker gland design, it is engineered for extreme duty in heavy industrial rotating equipment.

Industries Served

Oil & gas and petrochemical

process pumps operating under high pressure, high temperature, and requiring dual-seal barrier systems.

Chemical processing

large centrifugal pumps, high-duty reactors, and mixers where sealing integrity is essential.

Utility and power generation

feed water pumps, condensate return pumps, and critical auxiliary equipment where reliability is paramount.

Heavy manufacturing

large shaft drives, high-speed pumps, or compressors where cartridge style and heavy-duty materials improve service life.

Equipment & Use-Case Scenarios

- Process pumps built to API 610 (V8 or later) using dual-seal arrangements with external barrier fluid loops (Plan 53A/53B/53C).

- High-speed or high-temperature services (for example, up to 4,000 rpm or 392°F+) where self-aligning stationary faces reduce sensitivity to misalignment and thermal growth.

- Applications with aggressive, abrasive, or corrosive media where large barrier fluid orifices and vortex breaker design help manage debris and optimize barrier fluid flow.

- Engineered cartridge retrofit projects where shortening downtime is critical and changing to a modular seal solution improves maintainability.

Why It Fits These Applications

- Large ½″ NPT (or equivalent) barrier fluid ports enable higher flow volumes in the barrier circuit, enhancing cooling and reducing temperature rise at the seal faces.

- The integrated pumping ring ensures the barrier fluid flows effectively over both the inboard and outboard faces, improving face lubrication and heat dissipation and reducing leakage risk.

- Self-aligning stationary face design accommodates axial and radial shaft movement, improving face stability under challenging service conditions.

- Gland plate with vortex-breaker grooves helps protect the seal faces from slurry or particle ingress and prevents turbulent flow behind the seal, enhancing reliability.

- Cartridge-style construction simplifies installation and removal, reducing maintenance time and enabling faster turnaround.

Installation Guidelines

Start by cleaning and inspecting the shaft, seal chamber bore, and gland face. Verify alignment, finish, and that tolerances are within specification. Remove any scoring or corrosion.

Insert the SPW682-123 cartridge into the gland or onto the shaft with care. Ensure barrier fluid inlet/outlet ports are correctly oriented to the piping, and that the vortex-breaker gland plate is installed correctly.

Secure the set-screw drive to the shaft and tighten the gland clamp or bolts per specification. Connect the barrier fluid supply and return lines according to your barrier system plan (e.g., Plan 53 series) and vent the loop to remove air pockets.

Before full load operation, bring up the barrier fluid loop. Confirm flow, pressure, temperature, and fluid cleanliness are within expected ranges. Then start the pump under controlled conditions and monitor face temperature, barrier pressure, and vibration.

Record baseline parameters (barrier fluid pressure, face temperature, flow rate, pump speed) to support future condition monitoring and maintenance planning.

Maintenance & Inspection Best Practices

- Continuously monitor key parameters: barrier fluid flow rate, pressure different,ial across the filter/strainer, discharge fluid temperature, and condition of the barrier fluid. Any deterioration may indicate seal face wear or loop issues.

- During scheduled shut-downs, where feasible, remove the cartridge to inspect seal faces for wear or scoring, springs for fatigue, O-rings and gaskets for integrity, and the pumping ring for blockage or damage.

- Maintain a detailed operational log, including fluid chemistry changes, solids or particle ingress, shaft speed variations, start–stop cycles, and vibration or temperature excursions. Trend this data to anticipate maintenance and avoid unplanned failure.

- Replace secondary seals (O-rings, gaskets) at planned intervals and ensure the barrier fluid is maintained in the correct condition (cleanliness, temperature, chemical stability) to maximise seal life.

- If service conditions change (for example, higher temperature, higher shaft speed, increased solids, or more corrosive fluid), reevaluate whether the SPW682-123 remains suitable, or if an upgrade in seal materials or support-system configuration is needed.

Service & Support Options

- Pre-installation consultation to verify appropriate face material combinations (e.g., TC/TC, SiC/SiC, Car/SiC), elastomer compatibility, and the correct barrier fluid plan.

- Field or remote commissioning support to validate barriers and loop performance, measure seal-face temperature under load, and confirm correct installation and operating conditions.

- Spare-parts kits customised for the SPW682-123 cartridge, including seal faces, springs, O-rings/gaskets, pumping-ring components, set-screw drives, and gland hardware—facilitating prompt maintenance response.

- Upgrade path services: as your process evolves (higher speed, more aggressive media, higher pressure), you can upgrade to advanced metallurgy, alternate face materials, or enhanced support system configurations.

- Preventive-maintenance programmes that focus on trend analysis, condition-based alerts, and reliability reviews to increase mean time between maintenance, reduce the cost of ownership, and improve uptime.

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049