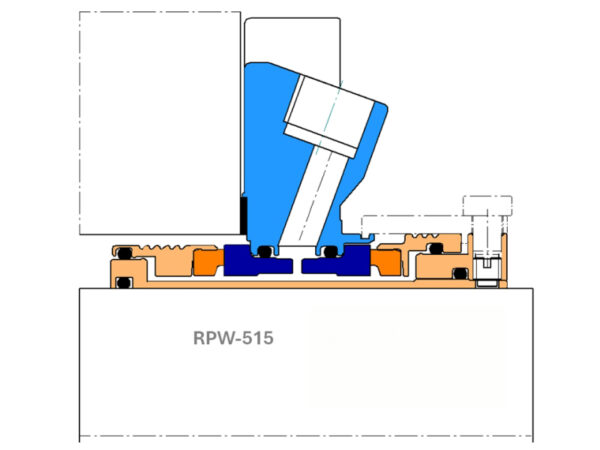

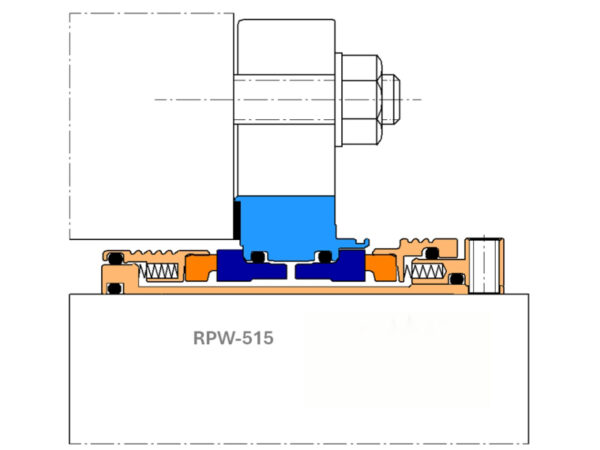

RPW-515 Mechanical Seal – Rotary Pusher Wet Single Cartridge Design

RPW-515 Mechanical Seal – Rotary Pusher Wet Single Cartridge Design

Overview

The RPW-515 by HydroMax Seal is a multi-spring, hydraulically balanced double cartridge mechanical seal designed with barrier fluid quench and drain ports and secondary O-ring seals for robust performance in rotating equipment applications.

This Rotary Pusher Wet (RPW) Double (515) Cartridge Seal features shrink-fitted seal faces and is built for use with parallel rotating shafts. Engineered with multi-springs for uniform face loading, the seal is set screw driven and includes a flush connection as part of a complete sealing solution.

Each unit is factory assembled and tested, ready for easy installation and reliable performance in process-critical environments.

Product Description

Key Design Features

- Large 3/8″ NPT Port Connections for flush, quench, and drain

- Cartridge Configuration: Pre-set seal faces eliminate the need for manual face load adjustment

- Easy Installation: Cartridge design ensures operator-friendly setup without performance compromise

- Multiple Material Options: Compatible with a wide range of process fluids and applications

- Fully Tested and Pre-Assembled: Delivered ready to install for minimized downtime

Technical Specifications

| Seal Shaft Sizes | 20 mm – 150 mm (1.000″ – 6.000″) |

| Inboard Seal Face Combinations | Carbon / Tungsten Carbide (Car/TC) Carbon / Silicon Carbide (Car/SiC) Tungsten Carbide / Tungsten Carbide (TC/TC) Tungsten Carbide / Silicon Carbide (TC/SiC) Silicon Carbide / Silicon Carbide (SiC/SiC) |

| Outboard Seal Face Combinations | Carbon / Tungsten Carbide (Car/TC) Carbon / Silicon Carbide (Car/SiC) |

| Gasket Material | GFT |

| Elastomer Options | Viton, ERP, Aflas, Kalrez |

| Maximum Shaft Speed | Up to 20 m/s |

| Process Fluid Pressure Rating | Up to 20 Barg |

| Barrier Fluid Pressure Rating | Up to 16 Barg (232 psig) – shaft size dependent |

| Pipework Compatibility | Plan 52 and Plan 53 systems |

| Temperature Rating | Up to 356°F |

Important Notice

Warning: The safe operating limits listed are based on each parameter considered individually. Do not use combined maximums for speed, pressure, and temperature without consulting HydroMax Seal’s technical team for your specific application.

Typical Applications & Industry Use Cases

The RPW-515 is a multi-spring, hydraulically balanced double-cartridge seal with quench and drain ports designed for high-duty rotating equipment using parallel shafts. It offers cartridge simplicity with the performance needed for demanding services.

Industries Served

Chemical and petrochemical processing

pumps handling aggressive fluids, high pressure, and critical uptime.

Oil & gas and refining

process pumps requiring dual-seal arrangements, barrier fluid management, and minimal environmental leakage.

Utility, power generation, and heavy industry

large pump trains or compressors where cartridge replacement and rapid maintenance are priorities.

General industrial equipment

rotating drives in systems where reliability, serviceability, and support-loop integration matter.

Equipment & Use-Case Scenarios

- Process pumps configured with a dual-seal barrier fluid system (for example,e Plan 52 or Plan 53 types) where quench and drain connections are standard.

- Parallel-shaft equipment requires a factory-assembled cartridge for fast installation and adjustment-free setup.

- Applications where shaft sizes range from ~20 mm to ~150 mm (1″–6″) and surface speeds approach ~20 m/s.

- Services where moderate to high pressures (up to ~20 bar process fluid and ~16 bar barrier fluid) and moderate temperatures (up to ~356°F) are in play.

Why It Fits These Applications

- Cartridge design means the seal comes pre-assembled and pre-set, reducing installation errors and downtime.

- Hydraulically balanced faces lower face loading and improve stability under pressure, temperature, and speed variations.

- A multi-spring arrangement ensures even loading of face pairs, improving wear characteristics.

- Quench, drain, and flush ports integrated as standard allow easy connection to barrier-fluid circuits and support loops.

- Factory shrink-fitted faces ensure correct face loading and help achieve controlled performance from day one.

Installation Guidelines

Ensure the shaft, seal chamber bore, and gland face are clean, true, and within specified tolerances. Remove scoring, deposits, or misalignment before installation.

Insert the cartridge seal carefully into the gland or onto the shaft; engage the set-screw drive securely and clamp the gland per instructions. Connect the quench, drain, and flush ports to your support system piping.

Commission the barrier fluid loop first: bring up flow and pressure, vent any air, verify cleanliness, correct orientation, then start the equipment under monitored conditions.

Confirm operating parameters are within the RPW-515’s specification: shaft size, surface speed, pressure, temperature, and fluid conditions. Record baseline values – barrier fluid flow, pressure, seal face temperature.

Begin full-load operation only after verifying that the cartridge, support loop, and piping are performing as expected.

Maintenance & Inspection Best Practices

- Monitor barrier fluid or quench loop performance continuously, including key indicators such as flow rate, pressure drop, filter condition, fluid cleanliness, and temperature rise. Any deviation may signal seal-face wear or a support-loop blockage.

- During planned shutdowns, if feasible, remove the cartridge for inspection: examine seal faces for wear or scoring, check springs for fatigue, verify O-rings/gaskets for integrity, and inspect quench/drain port passages for deposits.

- Maintain a detailed log of operating conditions, including shaft speed variations, changes in fluid chemistry or contamination, start-stop cycles, temperature excursions, and vibration events. Trends help predict maintenance intervals.

- Replace secondary seals (O-rings, gaskets) and refresh support-loop fluids and filters at scheduled intervals rather than only upon failure. Maintaining the barrier system's health extends seal life.

- If service conditions change – higher shaft speed, increased pressure, more aggressive media, or higher temperature – consult your supplier to evaluate whether the RPW-515 remains suitable or if a higher-duty model is required.

Service & Support Options

- Pre-installation technical review available to verify face-material selection (e.g., Carbon/TC, Carbon/SiC, TC/SiC), elastomer compatibility (Viton, Aflas, Kalrez), and quench/drain/flushing port configuration.

- Field or remote commissioning support to validate barrier-fluid loop flow, seal-face temperature measurements under load, and confirm correct installation and performance.

- Spare parts kits (seal faces, O-rings/gaskets, springs, set-screw drive components, clamp hardware) ensure maintenance turnaround is fast and efficient.

- Upgrade paths exist for evolving service demands – increased speed, higher temperature, more corrosive media – allowing migration to upgraded materials or alternate seal configurations.

- Preventive-maintenance programmes support condition-based monitoring, performance trending, and reliability reviews to increase mean time between maintenance and reduce total cost of ownership.

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049