RPW-215 Rotary Pusher Wet Cartridge Seal – Reliable Industrial Performance

RPW-215 Rotary Pusher Wet Cartridge Seal – Reliable Industrial Performance

Overview

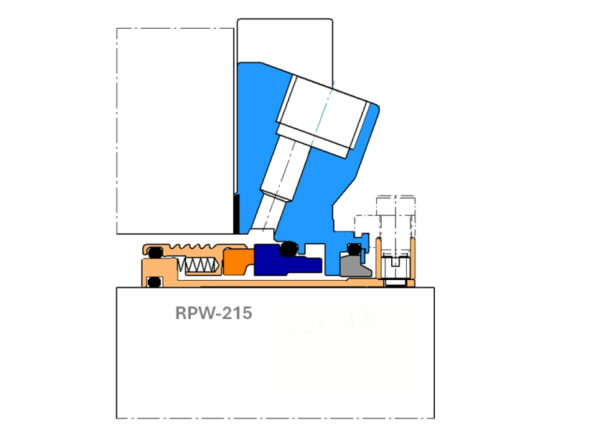

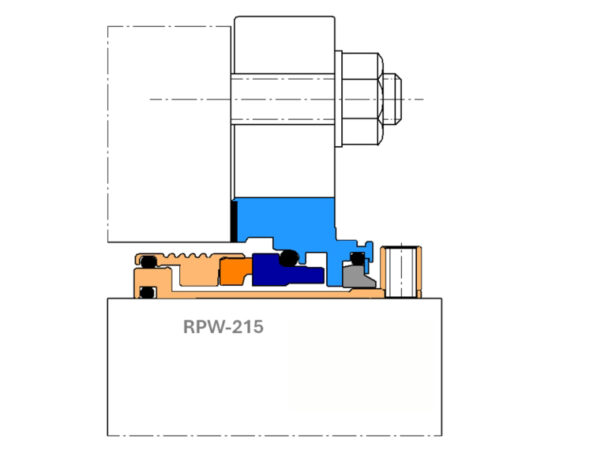

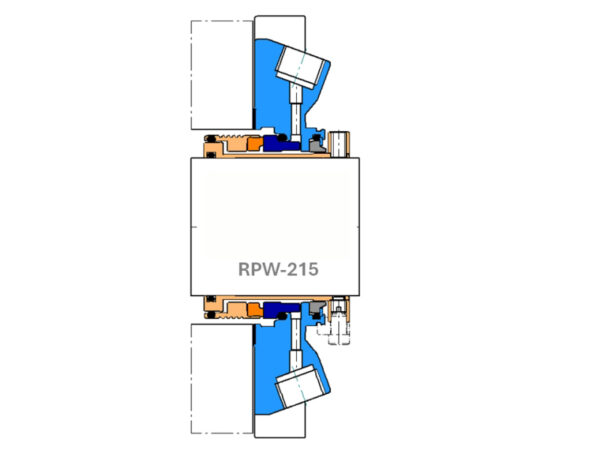

The RPW-215 by HydroMax Seal is a multi-spring, hydraulically balanced single cartridge stationary seal featuring flush and buffer fluid quench & drain ports designed for Plan 62 systems. It includes secondary O-ring seals for dependable performance.

This Rotary Pusher Wet (RPW) Single (215) Cartridge Seal features shrink-fitted seal faces and is designed for equipment with parallel rotating shafts. The multi-spring configuration ensures even face loading, while the set screw-driven cartridge design simplifies installation.

Additionally, the seal includes a flush port, quench and drain port, and an outboard floating restriction bush—all engineered for optimal operation in challenging environments. Each unit is delivered factory-assembled and tested for reliability.

Product Description

Key Design Features

- Rotary Seal Design

- Large 3/8″ NPT Port Connections

- Cartridge Configuration: Pre-set seal faces prevent incorrect face load settings, unlike component seals.

- Integrated Flush, Quench & Drain Ports: Compatible with Plan 62 systems for added sealing protection.

- Wide Range of Seal Face Material Options: Suitable for various process applications.

Technical Specifications

| Seal Shaft Sizes | 20 mm – 150 mm (1.000″ – 6.000″) |

| Inboard Seal Face Combinations | Carbon / Tungsten Carbide (Car/TC) Carbon / Silicon Carbide (Car/SiC) Tungsten Carbide / Tungsten Carbide (TC/TC) Tungsten Carbide / Silicon Carbide (TC/SiC) Silicon Carbide / Silicon Carbide (SiC/SiC) |

| Outboard Seal Face Combinations | Carbon / Tungsten Carbide (Car/TC) Carbon / Silicon Carbide (Car/SiC) |

| Gasket Material | GFT |

| Elastomer Options | Viton, ERP, Aflas, Kalrez |

| Maximum Shaft Speed | Up to 20 m/s |

| Pressure Rating | Up to 290.1 psig (process fluid) |

| Pipework Compatibility | Plan 11, Plan 32, Plan 62 |

| Temperature Rating | Up to 356°F |

Important Notice

⚠️ Warning: The safe seal performance characteristics listed above represent typical values for each variable independently. Do not apply upper limit values of speed, pressure, and temperature in combination without consulting HydroMax Seal for application-specific recommendations.

Typical Applications & Industry Use Cases

The RPW-215 is a premium multi-spring, hydraulically balanced single-cartridge seal built for parallel-shaft rotating equipment. It incorporates flush, quench, and drain ports to support varied seal-support system plans (including Plan 62 buffer or quench fluid systems). The unit comes factory pre-assembled and tested to minimise installation time and optimise reliability.

Industries Served

Chemical processing

service pumps handling moderate pressure, flush/quench required fluids.

Water & wastewater

booster pumps or auxiliary pumps where cartridge sealing and flushing support are beneficial.

OEM rotating equipment

compact installations where a cartridge design with quench/drain/flushing ports simplifies maintenance.

General industrial manufacturing

rotating equipment with moderate duty requiring improved sealing reliability and ease of replacement.

Equipment & Use-Case Scenarios

- Single-shaft pumps (or other rotating machinery) with shaft diameters ranging approximately 20 mm to 150 mm (1.0″-6.0″), matching the RPW-215 range.

- Applications requiring a flush or buffer-fluid quench due to product contamination, heat generation at seal faces, or drain requirements.

- Services with moderate shaft speeds (up to ~20 m/s) and process pressures up to ~20 bar – this seal is appropriate for these conditions.

- Installations where downtime must be minimised through rapid cartridge replacement, and where pre-set face loading simplifies commissioning.

Why It Fits These Applications

- The cartridge format means the seal comes pre-assembled and pre-set for consistent face loading—reducing installation error and ensuring performance repeatability.

- Hydraulically balanced seal faces help reduce face loading, improving wear performance, especially under pressure or speed variation.

- Multi-spring arrangement ensures evenly distributed loading across the faces, enhancing stability and service life.

- The inclusion of quench and drain ports expands support-system compatibility, enabling flush, buffer, or drain plans and allowing adaptation to process conditions requiring face cooling or contaminant removal.

Installation Guidelines

Prior to installation, ensure the pump shaft, seal chamber bore, and gland face surfaces are clean, straight, and within specified tolerances—remove any corrosion, scoring, or debris.

Carefully slide the RPW-215 cartridge into place; align the drive set-screw on the shaft as specified, clamp the gland/bolts per manufacturer instruction, and ensure flush/quench/drain ports are correctly oriented and connected.

Commission the flush/quench system: fill and vent the buffer or flush loop (if using Plan 62 or similar) before starting the pump under load.

Verify operating parameters are within the seal’s rated range: for example, shaft size 20 mm-150 mm, shaft speed up to ~20 m/s, process pressure up to ~20 bar, and temperature up to ~356°F.

Record baseline measurements: barrier/flush fluid pressure and flow, seal face temperature, and initial condition readings. These baseline values support future health monitoring and maintenance planning.

Maintenance & Inspection Best Practices

- Monitor flush/quench/drain system performance continuously: key indicators include flow rate, pressure differential across filtration, fluid cleanliness, and temperature rise. Deviations often signal seal face wear or system blockage.

- During scheduled shutdowns, remove the cartridge (if feasible) to inspect seal faces for scoring or wear, check springs for fatigue, evaluate secondary seals (O-rings or gaskets) for condition, and verify flush/quench loop components (strainers, piping).

- Maintain an operational log capturing shaft speed changes, fluid chemistry shifts (solids or contamination), flush/quench loop performance data, start-stop cycles, and any unusual vibration or temperature excursions. Use this historical data to trend performance and plan preventive maintenance.

- Replace secondary seals and refresh flush/quench loop fluids per a preventive schedule rather than wait for symptoms of wear. Maintaining the cleanliness and integrity of the support system significantly extends seal life.

- If process conditions change (increased speed, higher pressure, changed fluid chemistry, higher temperature), revisit the seal specification—confirm whether the RPW-215 remains appropriate or if a higher duty model is required.

Service & Support Options

- Pre-installation technical consultation is available to verify appropriate seal configuration: face material selection (Car/TC, Car/SiC, TC/TC, etc), elastomer options (Viton, Aflas, Kalrez), and flush/quench/drain port configuration for your support plan.

- Field or remote commissioning support can assist with flush/quench loop setup, measuring of face temperature under load, and verification of installation integrity.

- Spare parts kits are offered specific to the RPW-215 cartridge, including seal faces, springs, O-rings/gaskets, and set-screw/drive components to minimise maintenance downtime.

- Upgrade pathways exist: as service severity increases (for example, increased temperature or speed, more aggressive media, higher pressure), options include migrating to alternative face materials or a higher duty seal.

- Preventive-maintenance programmes that include performance trending, condition-based alerts, and reliability reviews help increase mean time between maintenance, reduce total cost of ownership, and improve equipment uptime.

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049