Heavy-Duty Slurry Seal SPS-610 – Durable Industrial Mechanical Seal

Heavy-Duty Slurry Seal SPS-610 – Durable Industrial Mechanical Seal

Overview

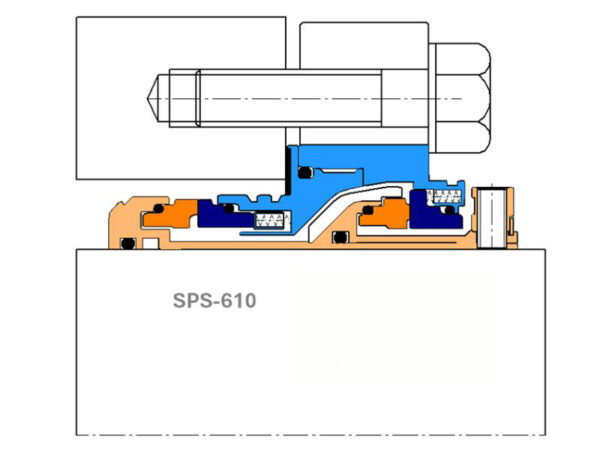

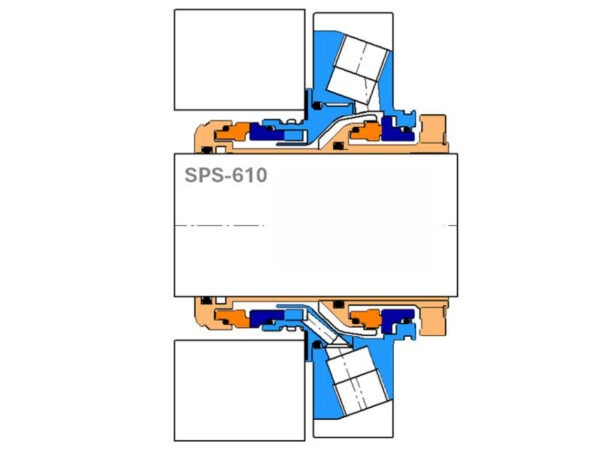

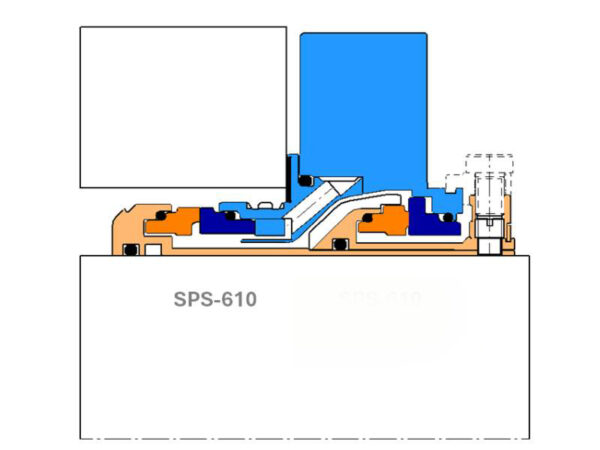

The SPS-610 by HydroMax Seal is a double cartridge mechanical seal equipped with an integral, bi-directional barrier fluid pumping ring. Specifically engineered for slurry applications, this seal is ideal for process fluids containing solid particles, commonly encountered in the Mining & Mineral, Pulp & Paper, and Water & Wastewater industries.

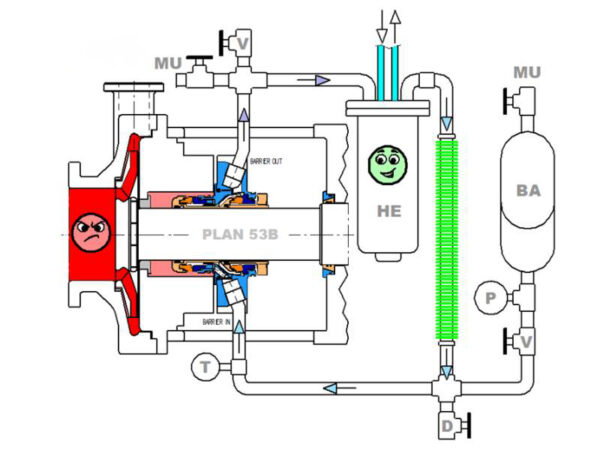

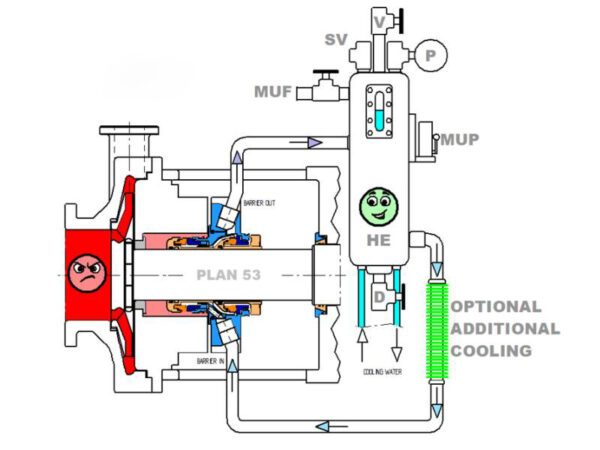

This innovative stationary design is delivered as a complete cartridge mechanical seal solution and is fully compatible with Plan 53, 53A, 53B, and 53C piping systems.

Product Description

Design Features

- Large Seal Port Orifices: 1/2″ NPT Barrier Fluid In (BI) and Barrier Fluid Out (BO) for Plan 53 or 52 systems.

- Efficient Heat Transfer: Barrier fluid flows to inboard seal faces via an integral deflector within the seal gland. The outlet, positioned above the outboard faces, enables effective heat dissipation across both sealing interfaces.

- Gland Insert with Vortex Breakers: Built-in inboard vortex breakers make this seal highly effective for slurry and solids-laden process media.

- API682 Compliant Clearances: Radial clearances between rotary and stationary components follow best-practice standards.

- Monolithic Seal Faces: Enhanced thermal performance in high-temperature environments.

- Self-Aligning Stationary Seal Face: Supports high-speed applications with improved stability.

- Multi-Spring Design: Springs are positioned outside of the process fluid for longer life and reduced wear.

- High-Efficiency Pumping Ring: Bi-directional design for optimized barrier fluid movement.

- Seal Support System Compatibility: Designed to work seamlessly with HydroMax Plan 53, 53A, 53B, or 53C systems.

Technical Specifications

| Seal Shaft Sizes | All sizes supported |

| System Vessel Sizes | 3.17 gallons and 7.40 gallons |

| Inboard Seal Face Combinations | TC/TC Car / TC Ant. Car / RB SiC Ant. Car / TC RB SiC / RB SiC |

| Outboard Seal Face Combinations | Car / TC Car / RB SiC Ant. Car / RB SiC Ant. Car / TC TC / TC |

| Gasket Materials | Spiral Wound Stainless Steel, Graphite |

| Secondary Sealing Options | Viton, Alfas, ERP, Kalrez |

| Maximum Shaft Speed | Up to 4,000 rpm |

| Pressure Rating | Up to 25 Barg |

| Instrumentation | Designed for integration with Plan 53 piping systems |

| Temperature Rating | Up to 482°F |

Built for Slurry Applications

The HydroMax SPS-610 is purpose-built for slurry handling where traditional seal chamber space is limited. Its advanced design delivers high-performance sealing in environments with suspended solids, without compromising reliability or service life.

Typical Applications & Industry Use Cases

The SPS-610 is a double-cartridge mechanical seal designed for heavy-duty slurry environments. Its rugged construction, bi-directional barrier-fluid pumping ring, and self-aligning stationary seat make it ideal for abrasive, solids-bearing fluids where standard seals fail prematurely.

Industries Served

Mining and mineral processing

Tailings lines, slurry transfer, cyclone feed pumps, mill discharge systems.

Pulp and paper

Pulp-stock pumps, grit removal systems, black-liquor processes.

Water and wastewater

Sludge pumps, grit systems, abrasive effluent handling.

Chemical and process industries

Slurry reactors, filter feed pumps, corrosive solids-bearing fluids.

Equipment & Use-Case Scenarios

- Pumps handling abrasive slurries where erosion, face wear, and contamination cause rapid seal failure.

- Applications with narrow or thin cross-section seal chambers that require a compact but robust double-cartridge seal.

- Systems using Plan 53-series seal support where barrier fluid cooling, filtration, and heat removal are essential.

- High-speed rotating equipment (up to approximately 4000 rpm) where seal face stability is critical under heavy slurry loads.

Why It Fits These Applications

- The bi-directional pumping ring produces strong circulation of barrier fluid, keeping seal faces lubricated and cool under abrasive service conditions.

- Large barrier-fluid ports allow higher flow volume, reducing heat generation and process-fluid ingress.

- The vortex-breaker gland design helps control particle movement and prevents slurry turbulence behind the seal faces.

- The seal is available in heavy-duty, corrosion-resistant materials such as 316SS, titanium, Hastelloy, and CD4MCU, well-suited for harsh slurry chemistry.

Installation Guidelines

Clean and inspect the pump shaft, seal chamber, and gland face to ensure proper alignment and absence of scaling, scoring, or debris before installation.

Insert the SPS-610 cartridge carefully to avoid damaging the pumping ring or misaligning the barrier-fluid ports.

Align the barrier-fluid inlet and outlet, secure the gland bolts, and tighten the set screws as specified to ensure proper drive engagement.

Charge and vent the barrier-fluid loop before pump startup to ensure proper lubrication and cooling during the initial rotation.

Verify operating parameters—shaft speed, pressure, temperature, and slurry solids concentration—are within the SPS-610 performance limits.

Maintenance & Inspection Best Practices

- Regularly check barrier-fluid flow, pressure, and temperature. Reduced flow or higher temperatures may indicate clogged passages or insufficient performance of the pumping ring.

- Inspect filter elements and barrier-fluid quality at routine intervals; contamination or poor lubrication significantly reduces seal life in slurry service.

- During planned shutdowns, remove the cartridge if possible to inspect seal faces, check for wear or scoring, and assess the integrity of O-rings, gaskets, and springs.

- Maintain a detailed operational log including changes in slurry concentration, pH, operating temperature, shaft speed, and pressure fluctuations.

- Replace secondary seals and refresh barrier fluid on a preventative schedule rather than waiting for performance decline.

Service & Support Options

- Pre-installation technical review to ensure correct material selection, barrier-fluid plan sizing, and proper fit within the seal chamber.

- Field or remote commissioning assistance to validate barrier-fluid flow, temperature stability, and overall circulation performance.

- Complete spare parts packages, including seal faces, O-rings, gasket sets, pumping-ring components, and filter elements.

- Upgrade pathways for evolving service demands, including alternate metallurgy, face-material changes, or enhanced support-system integration.

- Preventive-maintenance and reliability programs to reduce unplanned downtime, extend seal life, and optimise whole-system performance.

With proper installation, barrier loop commissioning, and disciplined maintenance, the SPS-610 offers a high-reliability sealing solution in the toughest slurry environments – combining cartridge convenience with heavy-duty robustness for mining, mineral processing, pulp & paper, water/waste, and aggressive process applications.

Related Products

Contact HydroMax Seal

Contact HydroMax Seal today for innovative solutions, expert guidance, and over a century of engineering excellence. Your journey to mechanical sealing excellence starts with HydroMax Seal!

E-Mail: sales@hydromaxseal.com

Address: 18511 Beaumont Hwy Building D

Houston, TX

77049